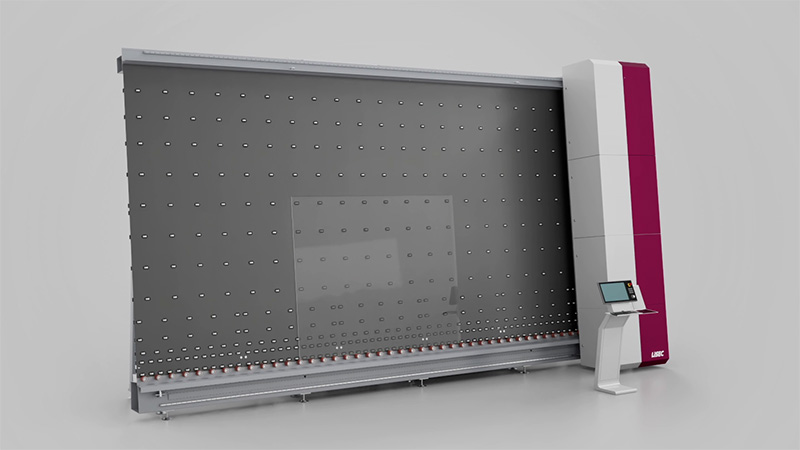

The precise surface treatment of large-format glass panes is a challenge in the flat glass industry. With the LSP-A vertical laser processing solution, LiSEC offers an innovative solution for removing coatings and precisely engraving surfaces. Thanks to its compact design and flexible configuration options, the LSP-A can be adapted to any production environment.

Technologies and applications

The LSP-A uses two different laser technologies as standard for a wide range of applications:

- CO2 laser for gentle surface treatment: Since the laser beam does not penetrate the glass, the desired texture can be applied precisely.

- NIR solid-state laser for the precise removal of paint, mirror coatings, enamel, low-E coatings, and even conductive coatings.

Depending on the laser technology selected, the LSP-A offers various specific applications, including:

1. Bird protection glass: Creation of patterns that are visible to birds and prevent collisions.

2. Flat engraving: Precise engravings on glass surfaces for decorative or functional purposes.

3. Marking: High-resolution markings for logos, text, or data codes for traceability and quality assurance.

4. Slip resistance: Structuring of glass surfaces to create non-slip properties, for example for floor coverings.

5. Edge decoating: Selective removal of coatings from the edges of glass panes.

6. Thin-film structuring: High-precision decoating of ultra-thin, barely visible lines on glass, e.g. for the production of frequency-transparent glass (signal glass) or heating glass.

Slip resistance |

Marking |

Flat engraving |

ADVANTAGES OF THE LSP-A

Thanks to the laser technology used, the LSP-A offers numerous advantages that set it apart from other processing technologies:

- Precision, accuracy, and quality

Thanks to contactless, mechanically stress-free processing, the glass is handled gently without causing mechanical stress. This results in low thermal stress on the material, which preserves the structural integrity of the glass. In addition, the LSP-A offers maximum resolution and contour accuracy, which is particularly advantageous for complex patterns and fine details. At the same time, high repeat accuracy is guaranteed, so that every piece of glass processed meets the same high quality standards.

- Cost-effectiveness and environmental friendliness

The LSP-A is characterized by minimal production costs, as no energy-intensive tempering or baking processes are required. In addition, no coolants such as water and no consumables such as paints or chemicals are required, which significantly reduces the environmental impact. Direct laser structuring of the glass surface is resource-saving and clean, and the end product is completely recyclable.

- Durability and flexibility

Laser-structured glass surfaces are resistant to weather, UV, abrasion, and temperature. They are less susceptible to fingerprints and dirt and retain their light transmission. LSP-A can be used on various types of glass, such as float glass, ESG, and laminated safety glass, and is also approved for use on tempered glass in Germany. LSP-A can be used either as a stand-alone solution or integrated into a production line as required, so that it can be used from the processing of raw materials to the finishing of IG units.

- Creativity and adaptability

See the LSP-A in Action

Summary

The LSP-A is the first LiSEC machine specifically designed for laser surface processing of flat glass. The vertical system enables precise processing of glass surfaces, including large-area engraving and coating removal. The compact design includes one or two movable laser beam heads and is available in various sizes and configurations to meet different requirements.