In modern glass processing, many companies face the challenge of processing insulating glass efficiently and without errors. High raw material costs and sustainability considerations make it essential to keep the error rate as low as possible. Especially in the manufacture of large-format glass elements, it is crucial that no damaged or contaminated panes enter the further production process.

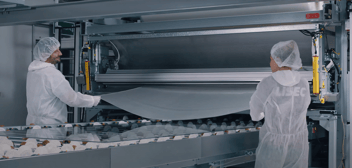

The new LiSEC FSI-A station offers a sophisticated combination of inspection and assembly assistance – specially developed for large and heavy glass elements.

Convenient Visual quality control

The station allows the operator to thoroughly inspect the glass surface. Thanks to integrated climbing aids at the front and rear every part of the glass pane can be easily reached. In addition, horizontally and vertically positionable LED strips ensure optimum illumination, making even the smallest defects visible. A special feature is the safety finger, which stabilises the pane during cleaning and prevents accidental tipping – a small detail with a big impact.

Features

- Walk-in area for full control: The rear area of the machine is accessible via a swivelling door in the line without any detours

- Maximum visibility and accessibility: Reduced interference contours ensure effortless inspection and access to the pane

- Climbing aids for optimum ergonomics: Foldable footboards and a mobile ladder allow the operator to safely reach the entire glass surface

- Flexible LED lighting: Integrated LED strips that can be positioned horizontally and vertically ensure perfect illumination

- Safety fingers: An intelligent safety mechanism prevents the pane from tipping forward during cleaning

Semi-automatic frame setting

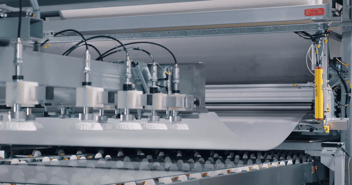

The inspection is followed by the assembly step: the station supports the operator with an intelligent assembly aid that first fixes the frame in place and then automatically aligns and positions it at the top edge of the pane. The remaining sides are pressed on manually – a semi-automatic process that increases both precision and safety. A particular highlight: the hooks on the assembly aid are height-adjustable, allowing the operator to insert the frame at a comfortable height.

Features

- Assembly aid for large frames: Special hooks and brackets securely transport the frame to the required position.

- Automatic positioning: The machine automatically presses the frame against the top edge of the pane. The remaining sides are pressed manually – a semi-automatic process that saves time and increases accuracy.

- Frame measurement: The station measures the profile width of the frame used and provides immediate feedback on whether the correct frame has been selected.

Flexible processing of steps

As standard, steps of up to 200 mm can be processed on the reference side (front edge or rear edge) of the FSI. Optionally, 0 - 1000 mm can be processed on three sides (front edge, top edge and rear edge). Steps of 150 mm are optionally possible on the bottom edge by means of continuously electrically adjustable horizontal stops. This results in maximum flexibility in the design options for glass façades and effortless production planning.

Find more information about automated step processing in the blog article: Perfectly stepped: Stress-free production of facade elements

LiSEC FSI - Inspection and semi-automatic assembly in one station

is the LiSEC FSI suitable for you?

Whether patio doors, façade elements or step glass – the station is designed for formats up to 6 x 3 metres and beyond, as well as for glass thicknesses up to 60 mm. This makes it ideal for manufacturers who work with large-format and heavy glass. This technology is proven in practice, already in use by customers worldwide and available immediately.

Learn more about our solution for glass inspection and frame assembly – contact us or visit our website.