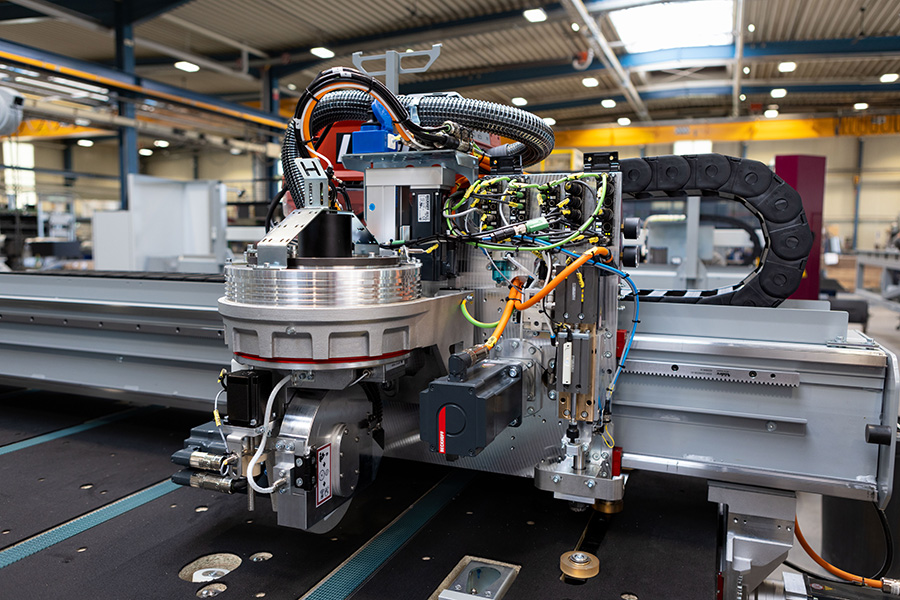

Efficient solutions for edge Decoating during float glass cutting

Float glass cutting may sound straightforward, but it plays a decisive role in ensuring quality, efficiency, and safety throughout subsequent glass production processes. With its DSC cutting technology, LiSEC delivers a solution that not only automatically selects the optimal parameters but also reliably removes complex heat and solar control coatings - perfect for anyone looking to maximize production performance.

glass-cutting

5 min read