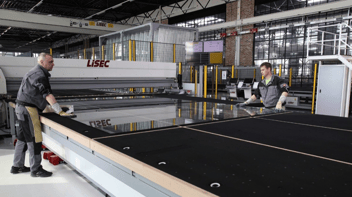

For 25 years LiSEC has been working at the highest international level with machines for cutting laminated glass. If there is one thing we have learned in this quarter of a century, it is the fact that improvements are always possible. And this is exactly what we - together with our numerous customers - have continuously worked on.

In keeping with the motto “Improving the tried and tested for lasting success”, we have developed a series of optimisation and retrofitting options for our customers' systems that lead to a significant increase in cutting performance and significantly better results. In this blog post, we would like to introduce you to the major advances that have been available since 2001.

If you think it is no longer possible, LiSEC will come up with the right solution.

Purchasing a new machine is not always the right answer to acute problems. This is because production sometimes has to be shut down for a certain period of time. Especially when you are in the middle of processing an important order and the deadline is mercilessly approaching, a quick and simple solution is usually required.

Even in such situations LiSEC has the right answers to ensure the economic success of its customers without interrupting or disrupting the production process. Among the most important innovations are the following three points:

- “Anti-stress” vacuum beam modification - increases fracture stability

- “SIR Selective Infra Red” foil heater - increases cutting performance

- Automatic cutting/crushing pressure control + “Cutting wheel monitor” HMI update - simplifies operation and reduces errors

1. “Anti-stress” vacuum beam modification

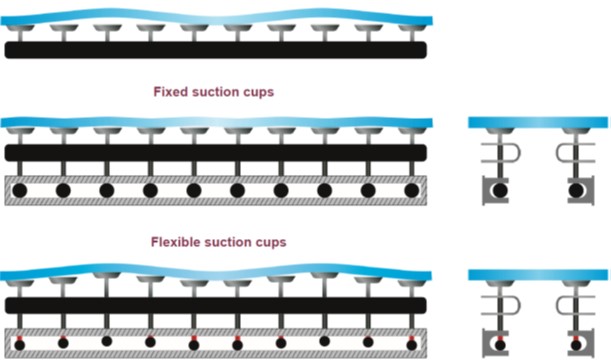

Laminated glass is already a very individual material. Very often, the individual sheets also come with a deformed or discarded surface, which can be traced back to production and storage. If these are then fixed to the flat working surfaces of the machines, this leads to tension in the glass, which in turn can lead to problems during cutting or crushing.

To prevent this phenomenon, the LiSEC “Long Life” department offers the “Anti Stress” vacuum beam modification, for example, which is suitable for systems from 2012. Each vacuum suction cup has a certain tolerance, which means that the machines adapt to the warp of the respective sheet so that no additional stress is applied to the glass.

The retrofitting process does not take longer than one working day. The pins of the suction cups are provided with a travel compensator to compensate for deformations in the tenth of a millimetre range. This significantly reduces false breakage.

Tip: If you have your machines retrofitted with the “Anti Stress” vacuum beam by LiSEC Long Life experts, then you will benefit double. This is because the technician not only carries out the modification, he also checks the parameters, adjusts them if necessary, supervises production and gives valuable tips for a perfect cutting result.

2. “SIR Selective Infra Red” foil heater

When cutting laminated glass, heating the foil is the work step that most influences the duration of the entire process. This means that an optimisation of this procedure also makes the greatest increase in performance possible and thus the energy saving potential is greatest. The aim is to heat the foil as quickly as possible and the glass itself as little as possible.

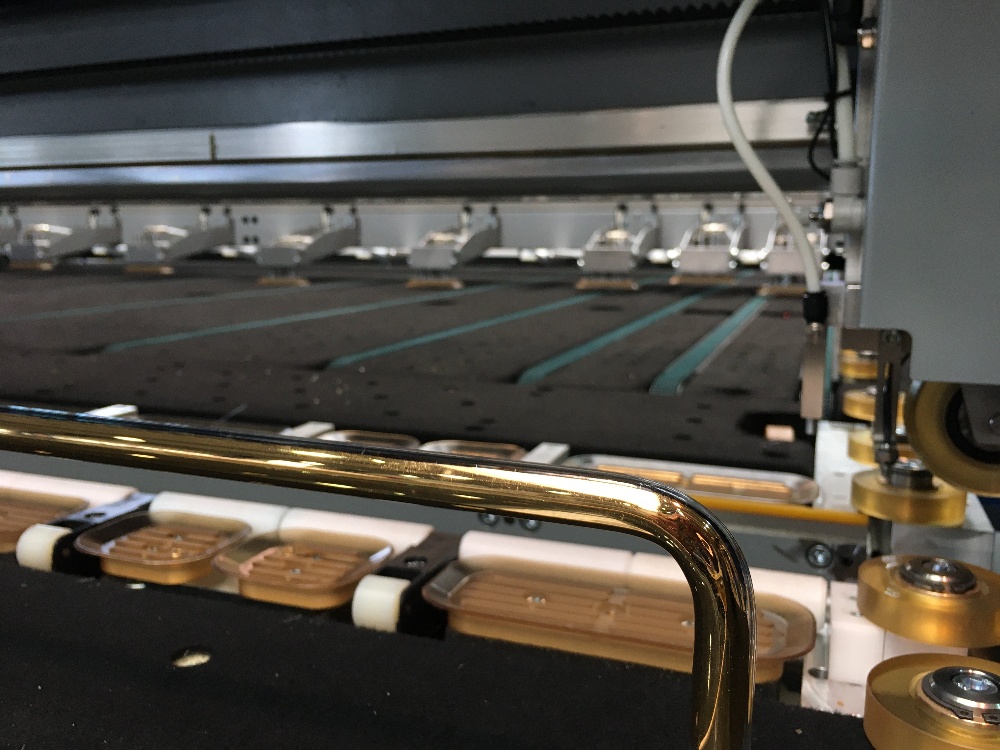

Since 2018 LiSEC has been using a segmented foil heater for this purpose - the SIR - Selective Infra Red foil heater - with which the heating time can be reduced to a 1/4. Depending on the cutting length of the system, heating modules up to seven 900 mm long are assembled in a row to form a unit. Compared to a continuous heating strip, this consumes significantly less energy.

In addition, the individual radiators are cheaper, much easier to transport and much less bulky to store. Moreover, only the module that is currently broken needs to be replaced and not the entire length.

Tip: If you have an existing system (VB/VBN) in use, then the heating modification is worthwhile in any case, as it can achieve a lot of performance and also save operating costs.

3. Automatic cutting/crushing pressure control + “Cutting wheel monitor” HMI update (Human Machine Interface)

As a rule, glass sheets of different thicknesses with different parameters are processed, cut and crushed on a daily basis. On older machines, the respective settings must be made manually. The automatic cutting/crushing pressure control provides a simple remedy in this respect.

With this optimisation, this happens automatically, which not only saves a lot of time, but also ensures smooth production. In addition, the number of operating errors, which are usually associated with additional costs, is reduced to a minimum.

In addition, an update of the visualisation can also be carried out as part of the retrofitting in order to update the HMI or the operation of the machine. This will make the numerous improvements that LiSEC has developed over the years fully available.

These include, for example, the cutting wheel monitor, with which each cutting wheel can be monitored and, if necessary, replaced in good time. In addition, the running meters are logged and the machine makes a recommendation for the optimum cutting wheel for the respective glass on the basis of the data stored in the recipe.

Tip: Writing down the cutting parameters on a piece of paper was yesterday. Today, laminated glass cutting 4.0 is the order of the day - the machine regulates the parameters automatically and autonomously. This saves time, costs and nerves.

Conclusion: How you can benefit from the improvements in glass cutting machines

Improvements to existing machines always pay off and actually pay for themselves. The “Anti Stress” bar, for example, demonstrably reduces the false breakage, which also lowers the overall operating costs. Optimisation of the foil heater leads to shorter cutting times and a more productive system. Thanks to automation, any operating errors can be eliminated. Incidentally: A machine of the latest generation has all these functions as standard.