The machines no longer set the pace alone. Increasing automation is expanding the sphere of influence of software-controlled intralogistics. Planning and optimization software is taking the place of a production manager who plans and tracks the route of the panes through the production. The software manages, controls, and monitors the production processes and provides ongoing status feedback. The pacemaker is the sorting buffer, which makes it possible to combine conflicting priorities in production. How does today's unmanned production work?

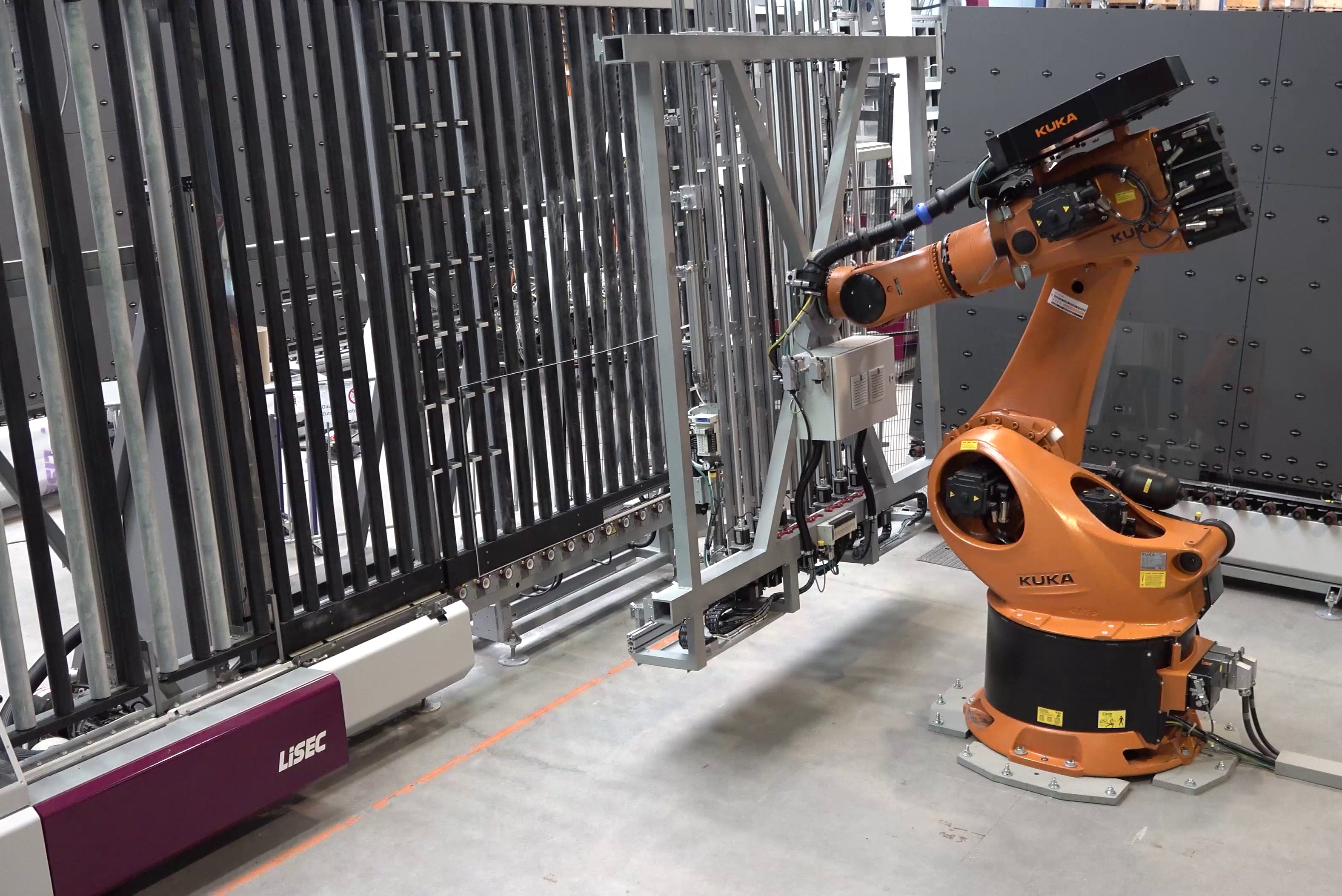

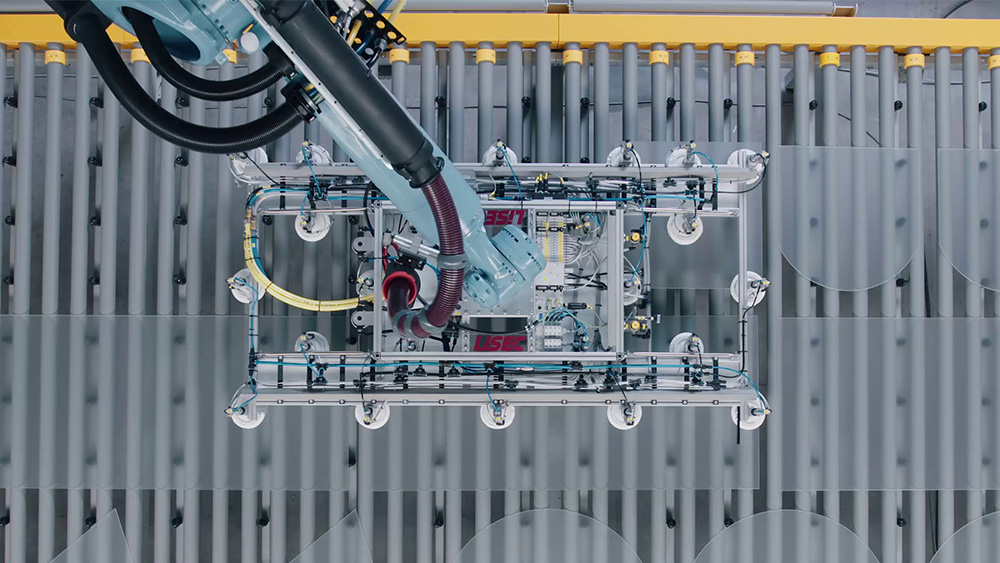

insulating-glass-production