Raw Glass Transport with Inloader Systems

Raw glass is typically transported using so-called inloader trucks. These consist of a standard tractor unit and a specially designed trailer. Inside the trailer is an inloader frame on which the glass sheets are transported upright. Common glass sizes are around 6 meters in length and 3.30 meters in height.

For unloading, the truck drives into the flat glass processor’s hall and automatically sets down the entire inloader frame. It then leaves the site, usually taking an empty frame back to the glass producer, where it is reloaded with raw glass. This creates a continuous logistics cycle between glass producer and processor.

Why Is Glass Transported Upright?

Vertical transport offers several advantages. First, it allows large glass formats to comply with legal road dimensions. If jumbo sheets were transported horizontally, even the narrower side of 3.30 meters would exceed permissible vehicle widths.

Second, weight is a critical factor. Inloader trucks already carry around 20 tons of glass. Horizontal stacking would increase weight further, requiring special transport solutions with higher costs, greater effort, and additional safety risks. Vertical transport has therefore become the efficient and safe industry standard.

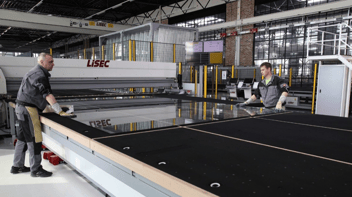

Internal Glass Logistics

Daily raw glass requirements dictate internal logistics and depend heavily on the size and capacity of the plant. Medium-sized processors often handle around 100 tons of glass per day, while large sites with multiple cutting tables, tempering furnaces, and insulating glass lines can process several hundred tons daily. Logistics here go beyond raw glass delivery—intermediate storage, internal transport, and staging of semi-finished products are equally important.

Fully Automated Glass Storage

Glass Racks, Storage, and Order Picking

- L-Racks: Loadable on one side, often placed along walls.

- A-Racks: A-shaped, loadable on both sides, ideal for central hall areas.

Between Cutting and Further Processing

Glass sheets pass through numerous steps such as cutting, edge processing, painting, enameling, tempering, laminating, or insulating glass production. Each step requires coordinated transport and buffering systems. After cutting, sheets are either manually or automatically removed and placed on racks. Modern plants use automated buffer systems to temporarily store and route sheets to subsequent processes.

Production planning and logistics software ensure smooth operations by managing sequencing, buffer utilization, and timely glass availability. In less automated plants, experienced production managers or shift supervisors handle this coordination manually.

Want to learn more about glass logistics? Check out our podcast LiSTEN LiSEC.