It is well known that laminated safety glass (LSG) is a material that is specifically processed because of its composition. But transport, storage space properties, handling, temperature, humidity, age of the glass and much more have another dramatic influence on glass cutting.

“The best glass and the best machine can have processing problems if the storage is counter-productive.”

Flat glass can be obtained in various qualities from the manufacturers and the quality naturally has an influence on the processing. This article, however, deals with influencing variables that each processing company has under control.

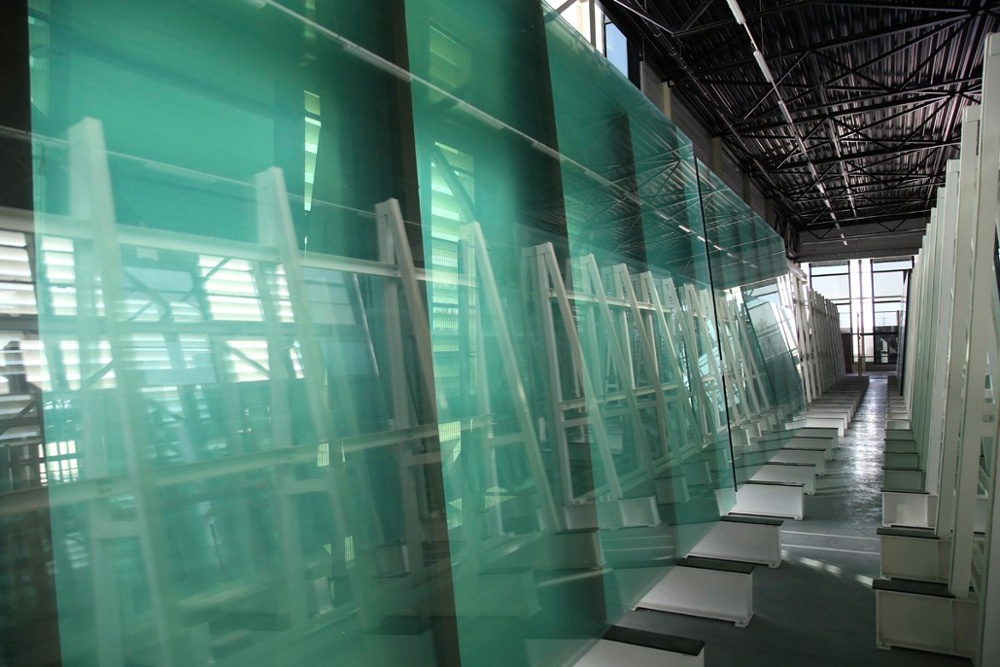

1. Glass storage

The delivery of the flat glass is carried out with internal loader trucks. The internal loader racks are picked up by the truck and usually transport 20 tonnes of glass, which is stored in glass packages on the frame. Glass packages of 2.5 t or 5 t are commonly used.

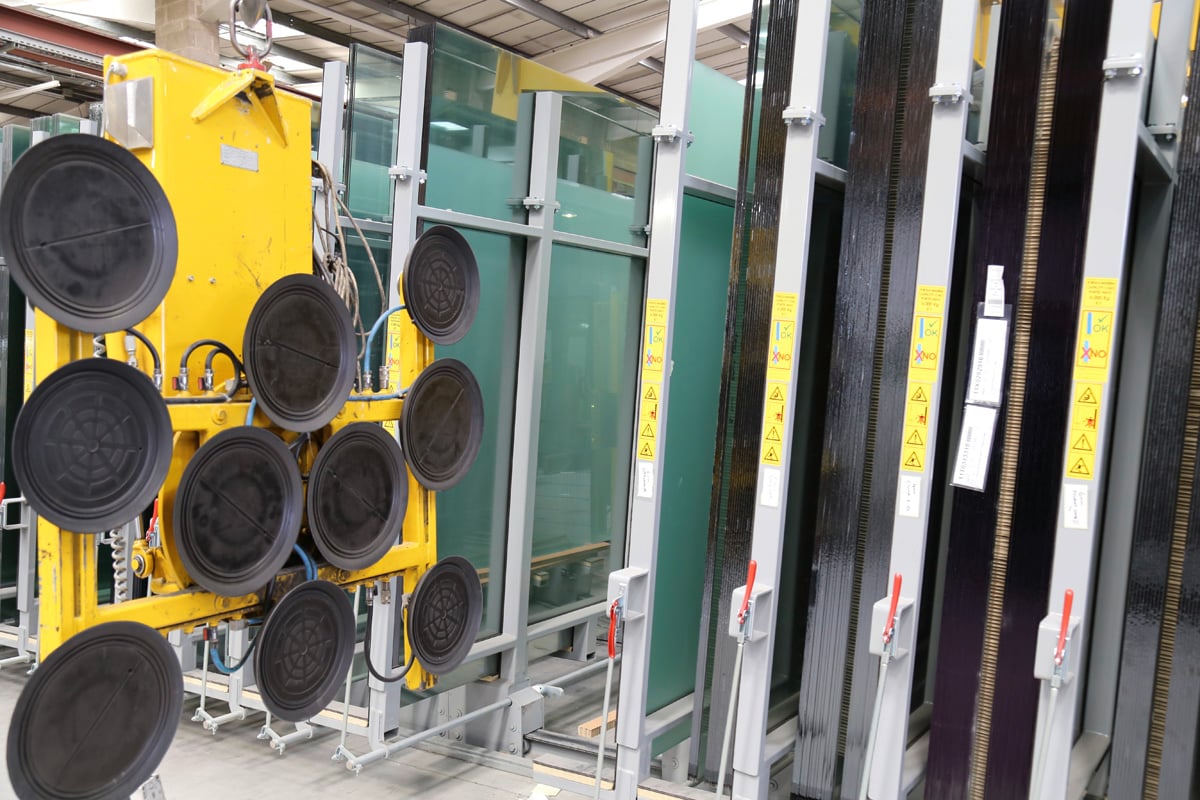

These individual packages are separated from each other by cardboard strips (spacers). The respective glass packages are individually placed in the storage areas by an employee in the glass storage with a lifting device attached to the gantry crane. The storage areas are L- or A-frames. These are simple steel constructions with a support surface on which the glass lites sheets stand.

It is not obvious at first glance that the storage racks have an influence on subsequent processing, but they do have a clear effect.

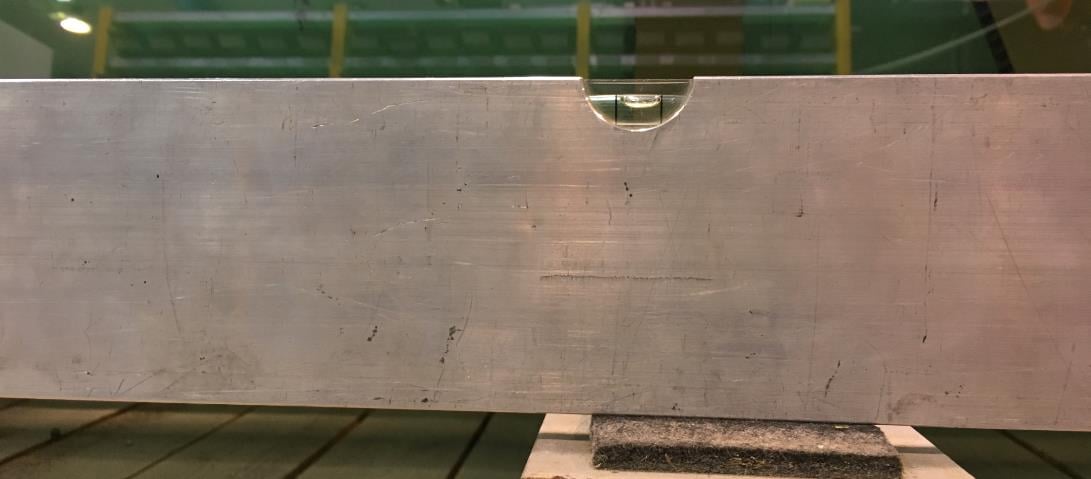

It is essential that the support surfaces remain at the same level. The glass edges must lie evenly on several support points and so the glass can be stored more or less free of stress (see image above). If, on the other hand, the supports are inclined or of different heights or the support surface is worn on one side, stress is induced in the glass, which can be noticeable in the glass cutting process through increased glass breakage.

2. Glass temperature and humidity

Hot, cold, warm, dry, moist: Essential factors that should be considered in order to optimise the glass cutting process. Laminated glasses consist of a laminated layer of two flat glasses joined together by a foil (PVB, EVA, Setry glass, etc.). Due to their physical properties, glass and foil have different temperature behaviour and this must be taken into account during processing, especially when glass cutting.

Glass is a brittle material. The colder the more brittle, the warmer the softer. The foil has similar properties, but unfortunately in a different temperature range. Air humidity also influences the properties of the foil.

Whether summer in Australia or winter in Norway - laminated glass is transported by truck and therefore assumes the ambient temperature during transport. In extreme cases, glass packages can have a core temperature of minus 20 °C to plus 60 °C on delivery. The acclimatisation of the glass to the temperature in the glass storage can take up to a few days!

There is no predetermined processing temperature on the part of the glass manufacturer. However, a processing temperature above 20 °C has a positive effect on the subsequent cutting process. Freshly delivered glass should acclimatise in the glass storage for 2-3 days. This way the glass cutting temperature can be kept stable and the glass storage always remains well filled.

Tip: When redesigning a production hall or expanding an existing one, it has proved successful to position the tempering oven close to the glass storage area. The waste heat thus automatically heats the glass storage.

3. Glass handling

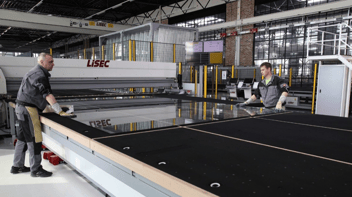

The 2 t or 5 t packages are placed in the storage area by the internal loader truck. From the glass storage to the cutting lines, however, the sheets must be transported individually. Please note that the glass loading or the handling device can also have an influence on the later processing.

Simple handling devices for manual loading usually consist of several vacuum suction cups attached to one design (see picture above). If the vacuum suction cups are arranged too tightly, central stress is created during the lifting process. A lifting device with vacuum suction arms that distribute the lifting forces over the entire surface should be preferred.

With automatic loading devices, care must be taken to ensure that they have a sufficiently large quantity of vacuum suction arms in order to distribute the forces better over the entire surface. It is better to use a FlyOver feed. A FlyOver feed has only one vacuum suction bar, which sucks in the glass sheet at the upper edge. The glass sheet therefore hangs freely and is not additionally clamped.

4. Stress in the glass

The glass is of the best quality, the storage is suitable, the temperature is in the ideal range and even the handling of the raw glass storage sheets does not introduce any additional stresses into the laminated glass, but nevertheless it is difficult to cut.

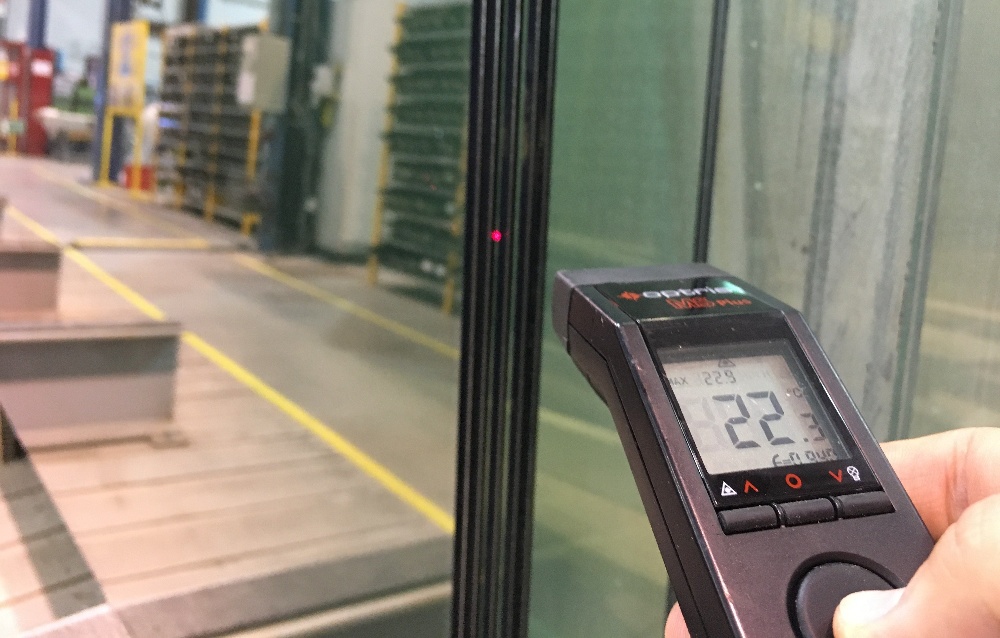

Often a glance into the glass storage is sufficient and stresses in the laminated glass can be visibly detected. Even if the flat glass sheets are apparently manufactured identically and flow out in a float glass plant on a tin bath, each individual glass sheet is unique.

Marginal unevenness is caused when two glass lites sheets are then joined by the foil to form a laminated glass, a raw material that is stressed in itself.

This stress pattern is very well visible in the glass storage (see image above arrow). Reflections of geometrically straight surfaces are no longer straight, but become waves or arcs. This is a clear sign of a stress range.

Experience has shown that the cutting parameters and tools such as cutting wheels must be adapted for such batches. If there is any doubt, then in some cases the only option is to complain to the glass supplier.

Conclusion: How the storage affects the glass cutting

Not only the quality of the laminated glass, but also its storage and handling must be taken into account during processing. In this case it depends on the supports of the glass frames, handling machines can create stresses and glass must acclimatise before processing. Before starting processing, it is worth taking a look at the glass storage: Stresses can easily be visually detected.