After seaming, grinding glass edges is another important work step in glass edge processing. The process is primarily used to remove overbreaks and underbreaks at the edges and to process the glass sheets to size. To this end, the edge processing removes an appropriate grind addition and the glass is thereby ground to the final size (custom ground edge "KMG"). This process also increases the edge strength, which significantly reduces spontaneous breakages. Glass lites sheets with ground edges exhibit a significantly higher strength against mechanical forces such as wind loads or thermal stresses. After grinding, the edge surfaces are matt ground and can sometimes also be used as visible edges. If the complete edge surface is ground, this is referred to as a finely adjusted edge ("KGN").

Flat glass lites sheets with ground edges are primarily used for façade and roof constructions in exterior architecture. Further to this, they are also used for photovoltaic systems, in the automotive industry, and in interior design elements.

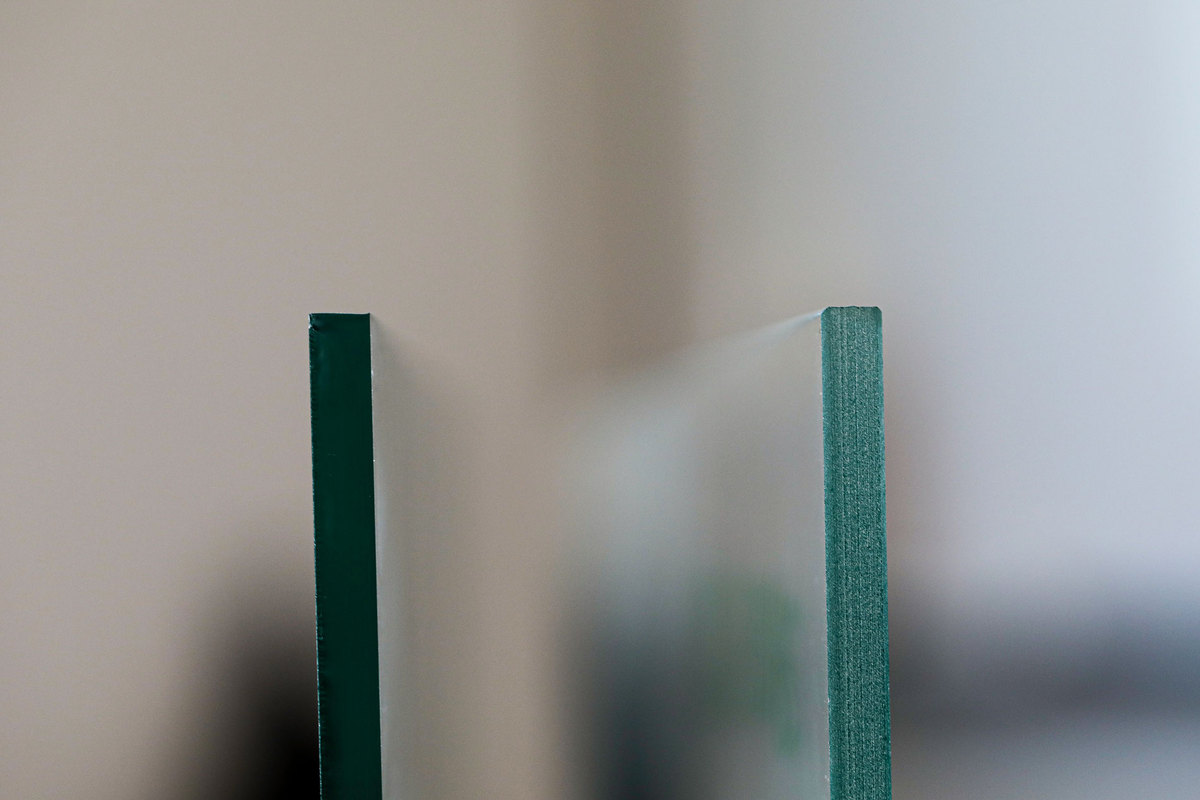

a cut edge in comparison to a ground edge

a cut edge in comparison to a ground edge

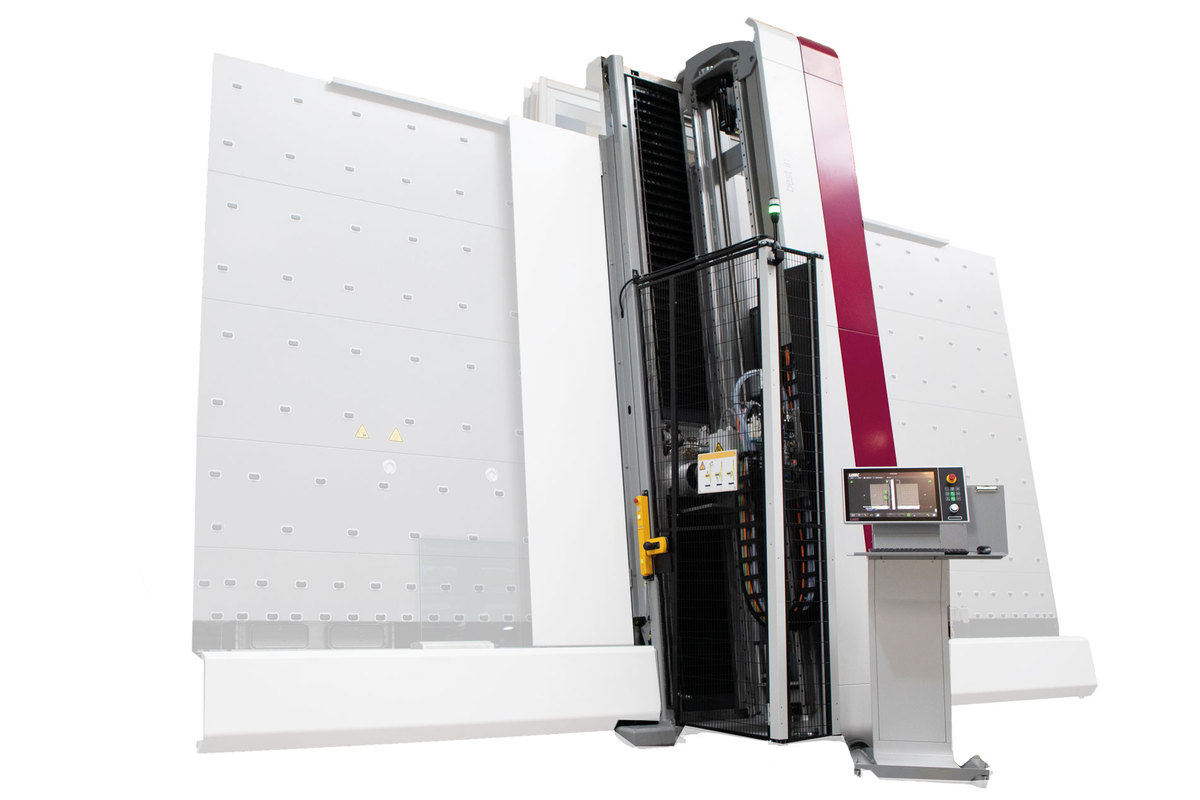

KSD-A vertical glass edge grinding system with patented LiSEC LiTEC-slider tool technology

Unlike most other manufacturers of glass processing machines, LiSEC also uses vertical station alignment for glass edge grinding. And does so for several reasons: The numerous advantages of these glass edge processing systems include significantly faster process execution, the maximum in flexibility from a batch size of just 1 and the processing of shapes. Furthermore, the KSD-A is not only currently the fastest vertical seaming and grinding machine with peripheral wheels for processing glass edges, it also reliably delivers the best, high-quality results thanks to the newly developed peripheral grinding wheels of the LiTEC slider series.

Moreover, the vertical process is far superior when grinding coated insulating glass because there is no contact with the sensitive coating on the front of the glass, thanks to LiSEC's patented contactless water cushion guide. This guide protects against scratches and ensures rapid and reliable production. However, the integrated water cushion does even more. It ensures a very high-quality finish without white streaks because it absorbs vibrations during the grinding process, and it increases the service life of the grinding wheel. Furthermore, the KSD-A can be used to grind numerous shapes such as triangles, trapezoids and glass sheets with arches. And what is more: Vertical grinding delivers maximum flexibility in modern flat glass processing thanks to the option of automatically changing grinding tools quickly and easily, and reacting to changes in glass thickness. This represents a significant step towards the just-in-time production of top quality flat glass with glass edge processing.

Build-up of the KSD-A

The KSD-A can be individually tailored to specific requirements, thanks to its modular construction. At the very core of the system lies the processing tower with a high-speed X-axis for glass transport. One or two processing heads can be used as required, to reduce seaming and grinding cycle times and increase throughput. The axes are optimally sealed against moisture, which keeps the process stable for a very long time and significantly reduces maintenance costs.

Die KSD-A

Die KSD-A

The glass sheets to be processed are picked up by the high-speed X-axis by means of suction pads. The length and height of the glass sheet are measured "on the fly". Grinding to size is only possible due to this integrated sheet measurement. Furthermore, seaming and grinding can be carried out in any number of cycles to ensure the desired edge quality. The flexible tool configuration of the KSD-A also facilitates the convenient processing of varying glass thicknesses without a need for tool changes. This saves a great deal of time, and ultimately also money.

Stable and high-quality edge processing

The KSD-A from LiSEC is the ideal solution in particular for insulating glass processing operations that require flexible and stable glass edge processing, whereby there is no requirement for each individual work step to be controlled or initiated by manual intervention. It is universally applicable and always delivers top quality. Thanks to the numerous configuration options, the system is ideally suited for the completely flexible processing of individual sheets and can be optionally integrated into LiSEC production lines.

Further advantages of the KSD-A from LiSEC include the fully automatic infeed and outfeed of the glass sheets, as well as the option of grinding completely without glass removal. Operation of the system is extremely straightforward and intuitive due to the graphic interface. An optional second processing head can be fitted for even faster cycle times, making it possible to carry out rough and fine grinding in a single operation.

The advantages of the KSD-A at a glance

- High-quality grinding results from a batch size 1

- Seaming and grinding in the shortest cycle times – optional second processing head for even faster cycle times

- Includes sheet measurement

- Perfect waterproofing of all axes for maximum availability

- Easy access for service and maintenance work

The most common grinding tools

LiSEC's glass grinding unit KSD-A uses patented LiTEC-slider metal peripheral grinding wheels, with abrasive diamond material. The advantage of the newly developed LiTEC slider grinding wheels is that they are not subject to vibrations thanks to a special water cushion guide system and can adapt to any warping in the glass sheet. This ensures a homogeneous, high-quality grinding result and also provides optimum cooling.

Thanks to the vertical construction, the water consumption is much lower than with horizontal systems, which are open at the top and are therefore also prone to evaporation and carry-over.

Peripheral grinding wheels are available in different degrees of roughness depending on requirements, and are optimally suited for different forms of grinding such as so-called trapezoidal grinding or C-grinding.

|

The most common grinding tools for external processing:

|

Conclusion

Grinding is a highly complex work step within the framework of glass edge processing. First and foremost, it is important that the ground glass edges are of impeccable quality so that further glass sheet processing steps are executed optimally and seamlessly. Furthermore, the glass sheets must fit the respective dimension precisely after grinding or - in the case of interior applications - deliver an excellent surface experience. LiSEC's innovative KSD-A glass grinding machine is a state-of-the-art vertical system that offers the maximum in flexibility and delivers high-quality results within the shortest cycle times.

-1.jpg?width=352&name=beitragsbild1-allgemein-beitrag4-glass-polishing-edge-processing-lisec.2022%20(1)-1.jpg)