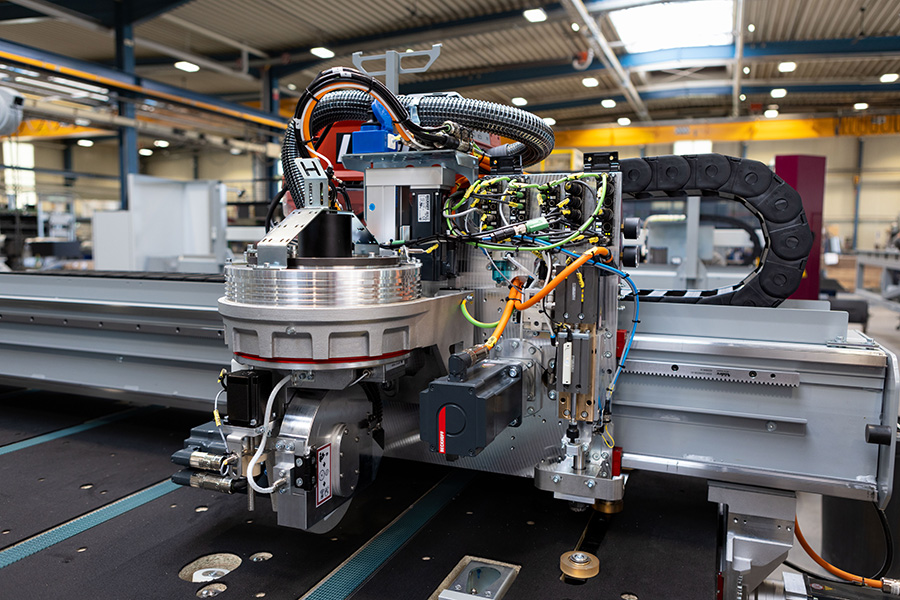

The decoating process is influenced by numerous factors, including the type, diameter and width of the grinding wheel, the rotational speed, the decoating speed and the type of coating. These parameters can have a significant impact on the quality of the edge decoating, especially if one factor causes the grinding wheel to overheat during the decoating process.

The consequences: uneven results, increased wear and unnecessary costs. With LiTEC Temperature Control, LiSEC has developed a solution that addresses precisely this issue – for greater process reliability, quality and efficiency.

How does LiTEC Temperature Control work?

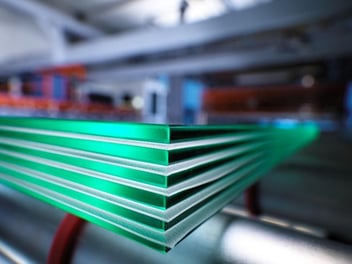

In glass cutting, the edge delamination process involves high temperatures, especially with triple silver coatings or TPF or EASYPRO® coatings.

The result: the grinding wheel no longer works reliably at high temperatures and the delamination quality decreases. This is exactly where LiTEC Temperature Control comes in: an intelligent system for temperature monitoring and temperature control.

The system continuously measures the temperature of the grinding wheel using a protected sensor positioned on the side of the grinding wheel guard. If a critical temperature (definable via parameters, standard approx. 180°C) is exceeded, air cooling is automatically activated. This ensures that the grinding wheel is quickly brought back to a non-critical temperature level.

The cooling is designed to have as little impact as possible on the cycle time of the system. Two cooling modes are available:

- Short-term cooling during the optimisation of individual processes

- Long-term cooling after each decoating process to prevent temperature accumulation

The temperature is measured indirectly to avoid contamination and measurement errors – the sensor is protected by a window and is easy to clean.

What are the advantages of this system?

- Consistent decoating quality: Temperature-related fluctuations are a thing of the past.

- Less wear: The grinding wheel lasts longer at lower temperatures, which saves costs.

- Operator independence: The system reduces errors caused by manual misadjustments.

- Higher degree of automation: Greater process reliability and fewer interventions.

LiTEC Temperature Control in ACtion

How can you obtain LiTEC Temperature Control?

If you are using a new DSC system with edge stripping unit from LiSEC, LiTEC Temperature Control is already integrated as standard. For existing DSC systems, retrofitting is generally possible – please contact your LiSEC representative for more information!

A special bonus: You currently receive the system free of charge with your order of a new DSC cutting table!

The solution is not currently available for machine types such as ESL-RS or GFB.

Conclusion

LiTEC Temperature Control is an intelligent system for temperature monitoring during the edge delamination process. It protects against overheating, ensures quality, extends the service life of the grinding wheel and reduces operating errors. Customers benefit from a more stable, efficient and future-proof process – as standard or as a retrofit solution.