Laminated Glass: Invisible Protection with High-Tech Potential

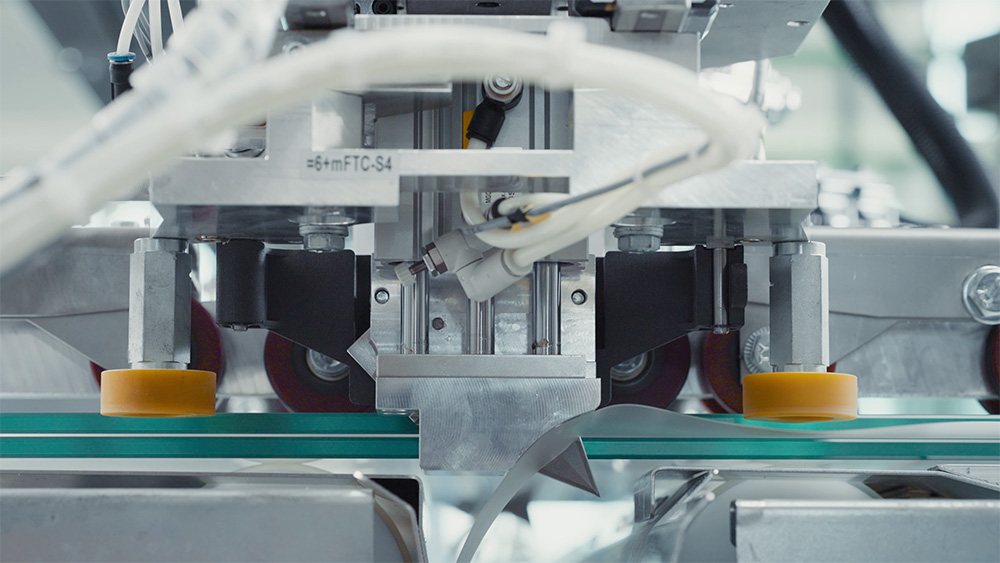

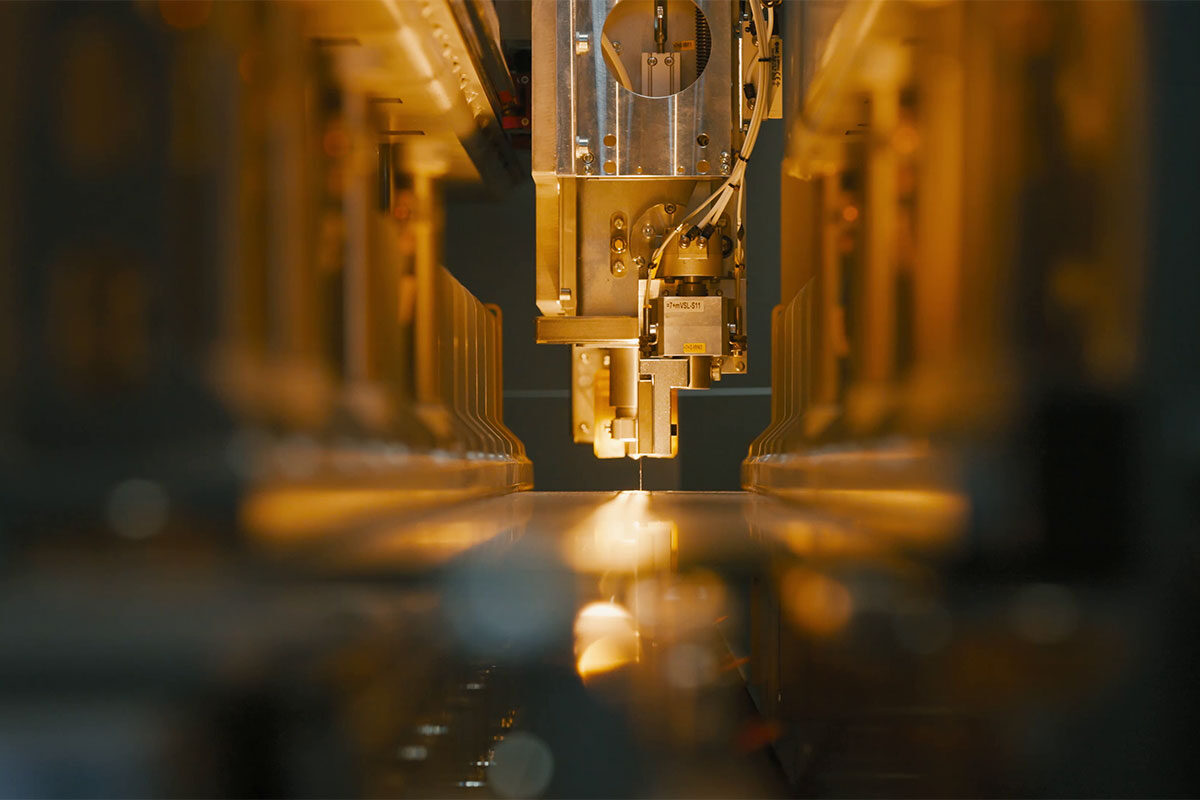

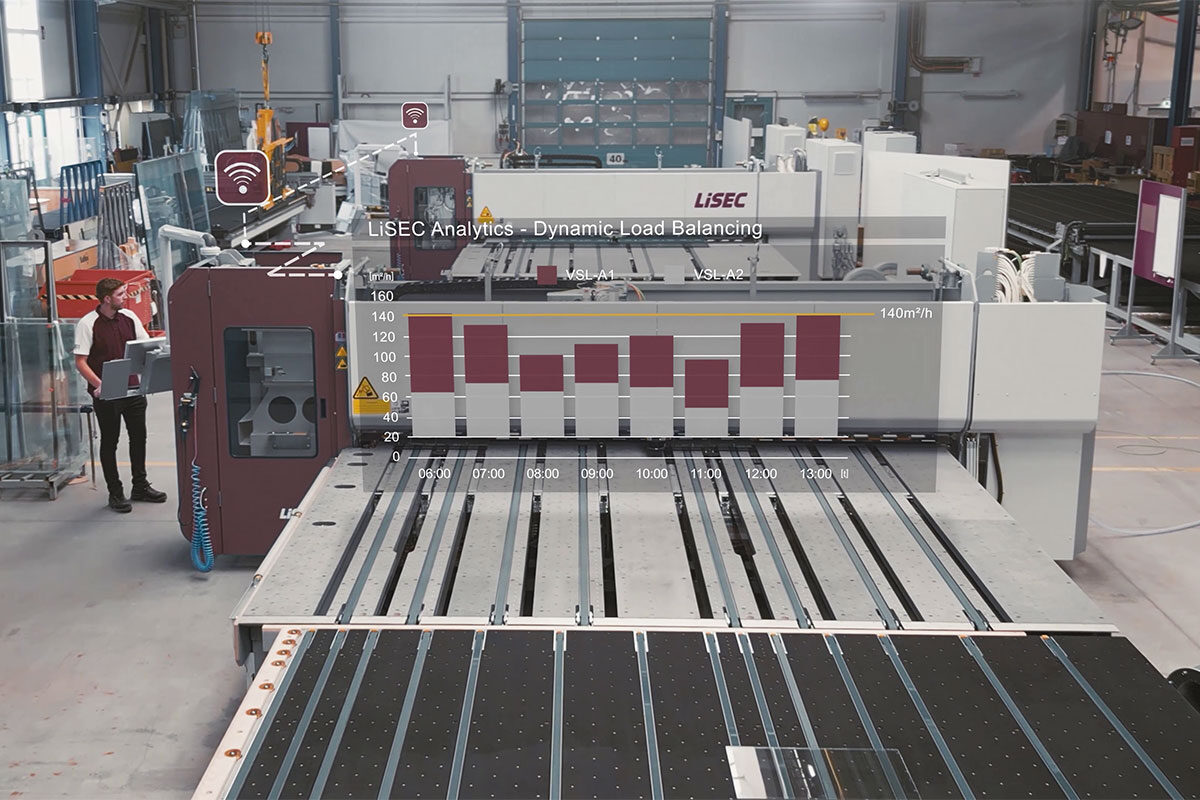

Laminated glass plays an important safety role: the combination of glass and interlayer film ensures stability and security, protecting against injuries in the event of an accident. But how does this invisible protection work? How is the complex bond between glass and film created—and what innovations are making laminated glass a true multi-talented material today? You’ll find the answers in this article.

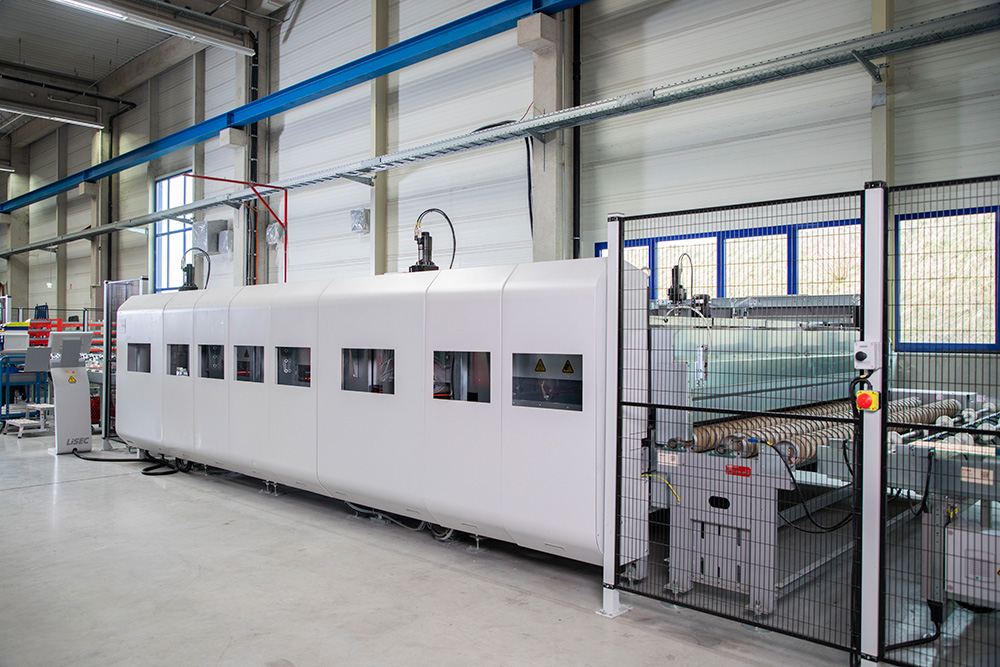

laminated-glass-production

5 min read