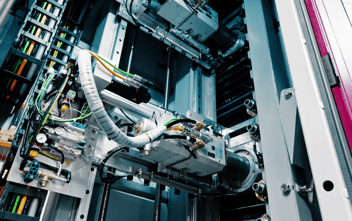

High-precision manual measurement of glass panes is difficult for rectangular panes up to a certain size - and almost impossible for oversized panes, special shapes or panes with internal processing (such as holes and cut-outs). The LiTEC Accurate quality control station with new suction cup technology was developed to simplify and automate this process.

HOW THE QUALITY CONTROL STATION WORKS

- The glass is measured as it passes through the scanner.

- The suction cup axis informs the scanner of the exact longitudinal position of the glass

- The scanner combines the individual images into one and saves it for further analysis

WHAT ARE THE ADVANTAGES OF ACCURATE GLASS MEASUREMENT IN THE PRODUCTION

- Continuous automatic measurement of all panes in the production flow

- Operator intervention only necessary if faults are detected

- Identification of production errors before delivery

- Rapid detection of faulty processes, and therefore fewer affected end products

- Compensation of tolerances through active corrections

- Increased process stability

LiTEC Accurate in Action:

EXAMPLES OF USE

At the IG LINEIn the IG line, LiTEC Accurate measures the exact size of the glass pane and checks the correct alignment of shapes. |

|

AT the Processing lineAfter the processing machine (from LiSEC or other manufacturers), the entire contour of the glass pane can be checked. Both the outer contour and the inner processing (size and position) can be checked. |

|

Highly precise |

|

The system has an accuracy of +/- 0.5 mm within 1000 mm glass length and 0.1 mm per additional linear meter.

For highest accuracy a processed edge (at least seamed) is necessary.

|

.jpg?width=352&name=MRX-B_0003_Update%20(1).jpg)