In today's manufacturing industry, companies are faced with the challenge of optimizing their production capacities to avoid bottlenecks and increase efficiency. Precise and flexible capacity management is crucial to optimizing production and responding quickly to changes in demand or in the production process.

lis.capacity: the LiSEC Solution

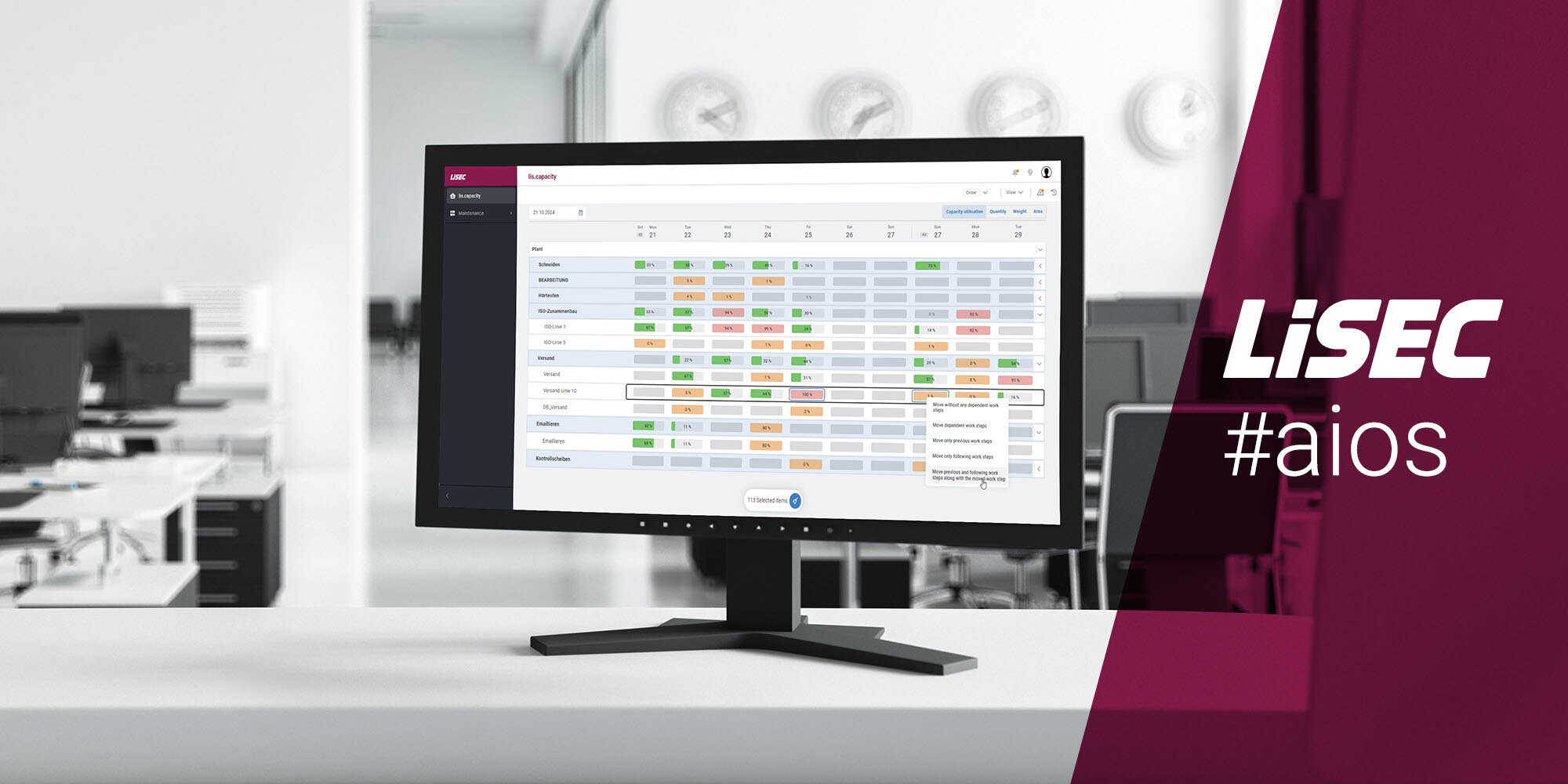

With lis.capacity, LiSEC offers an innovative software solution that helps companies to monitor the utilization of their production plants in real time and to use their resources efficiently. This solution makes it possible to transparently analyze capacities, to flexibly react to production changes and to adjust the utilization at any time in order to ensure maximum efficiency.

FUNCTION OF lis.capacity

lis.capacity is based on the capacity calculation data and feedback from your production facilities and displays it in a clear, easy-to-use interface. The software provides comprehensive insights into the current capacities and utilization of machines and resources. Production managers can use the data to identify bottlenecks at an early stage and manually adjust capacity utilization to ensure smooth production processes. Thanks to real-time monitoring, companies are able to react quickly to unexpected production changes and reorganize production planning accordingly.

OPTIMIZED CAPACITY MANAGEMENT WITH lis.capacity

The efficient use of production capacity is a key success factor in industry. lis.capacity offers companies the flexibility to carry out both short and long-term capacity planning. The software supports two approaches:

The first approach is reactive capacity management. Here, production capacities are monitored and, if necessary, adjusted manually in order to react to changes in production. Bottlenecks can be identified at an early stage and compensated for by flexibly adjusting capacities.

The second approach is proactive capacity management. In this case, production planning takes planned capacities into account so that resources can be optimally allocated. This leads to long-term optimization of production capacity utilization and minimizes idle times. Production is controlled in such a way that the maximum possible capacity is always used without overloading the production processes.

With these two approaches, lis.capacity offers a flexible and efficient solution for making optimum use of capacities and continuously improving production processes.

EFFICIENT CUSTOMIZATION AND MONITORING WITH lis.capacity

lis.capacity offers an intuitive and user-friendly interface that allows production capacities to be manually reorganized and adapted to unexpected changes. Real-time monitoring ensures that production managers always have a complete overview of current capacity utilization and can make any necessary adjustments directly. The transparency and flexibility of the software significantly increases the efficiency of the production process.

CENTRAL PLANNING AND MONITORING WITH lis.capacity

lis.capacity acts as a central platform for planning and monitoring production capacities. The software continuously collects up-to-date data and ensures that production managers can make informed decisions based on comprehensive analyses at all times. This enables capacity planning to be seamlessly integrated into the entire production process and ensures that the available resources are always optimally utilized.

FLEXIBILITY THROUGH MANUAL REORGANIZATION

A key feature of lis.capacity is the ability to manually adjust production capacity utilization. This gives companies the flexibility to react quickly to unforeseen changes in the production process and avoid bottlenecks. In this way, production capacities can be efficiently rescheduled to maintain the production flow and minimize downtimes.

TECHNICAL REQUIREMENTS

The use of GPS.Prod version 4.15 is required for lis.capacity to be used. This version ensures smooth communication between production planning and capacity management.

PRODUCT AVAILABILITY AND NEXT STEPS

lis.capacity is available immediately and will be set up by LiSEC service personnel. Contact us for more information and to manage your production capacity more efficiently.