Foil cutting is a challenge in laminated glass production. Manual cutting of the foil not only carries a high risk of injury, but is also time-consuming and costly. How to ensure reproducible quality for laminated glass? LiSEC offers an answer.

Recurring problems with manual Foil cutting

- High risk of injury

- Time-consuming

- Movement of the pane causes misalignment in the laminate

- Contamination in the laminate due to manual handling

- Foil pulls back at the edges or forms bubbles due to inaccurate cutting

- Processing of large elements is difficult

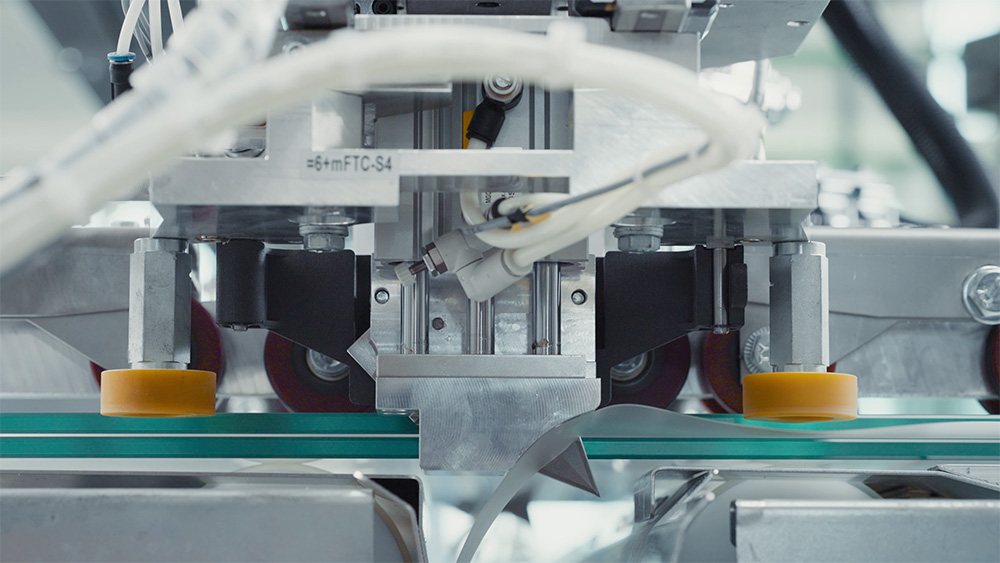

The Solution: Automatic Foil cutting with the FTC-C

The challenges of manually seaming the foil... |

...end with automatic processing. |

This is where the LiSEC solution “FTC-C” (Foil Trim Cut) for automatic foil cutting comes into play. Automatic handling and precise cutting of the foil ensure consistent quality. This reduces the risk of injury and increases efficiency.

The FTC-C processes rectangular, double-layered, laminated glass fully automatically and precisely, from a minimum size of 600 x 400 mm (LxW) up to a maximum width of 3.3 m and a definable maximum length (current models process up to 12 m).

Watch the FTC-C in action:

The Advantages at a glance

- Fully automatic processing of rectangles

- Supports processing of numerous foil types

- Cutting widths up to 3300 mm

- Processing of up to 50 mm foil overlap on the reference side and front and rear edges, and up to 500 mm foil overlap on the counter-reference side

- Desired foil overlap can be individually adjusted

- Higher material throughput thanks to 2 work stations

- Easier processing of large elements

- Greater efficiency

- Less waste

- Perfect quality with every pane

Summary

The LiSEC FTC-C offers a fully automatic solution for precise foil cutting, which improves product quality and minimizes production risks while increasing efficiency.