Float glass cutting may sound straightforward, but it plays a decisive role in ensuring quality, efficiency, and safety throughout subsequent glass production processes. With its DSC cutting technology, LiSEC delivers a solution that not only automatically selects the optimal parameters but also reliably removes complex heat and solar control coatings - perfect for anyone looking to maximize production performance.

Where Are the Challenges in Float Glass Cutting?

In glass processing, cutting float glass is a critical step with several challenges:

- Quality variations in raw glass affecting edge strength and process stability during breakout.

- Production bottlenecks during peak periods when existing systems cannot deliver sufficient throughput.

- Uncertainty with new coatings - Can current edge-decoating technology handle them quickly and reliably?

- Lack of process control over cutting parameters, leading to quality losses.

The Technological Solution

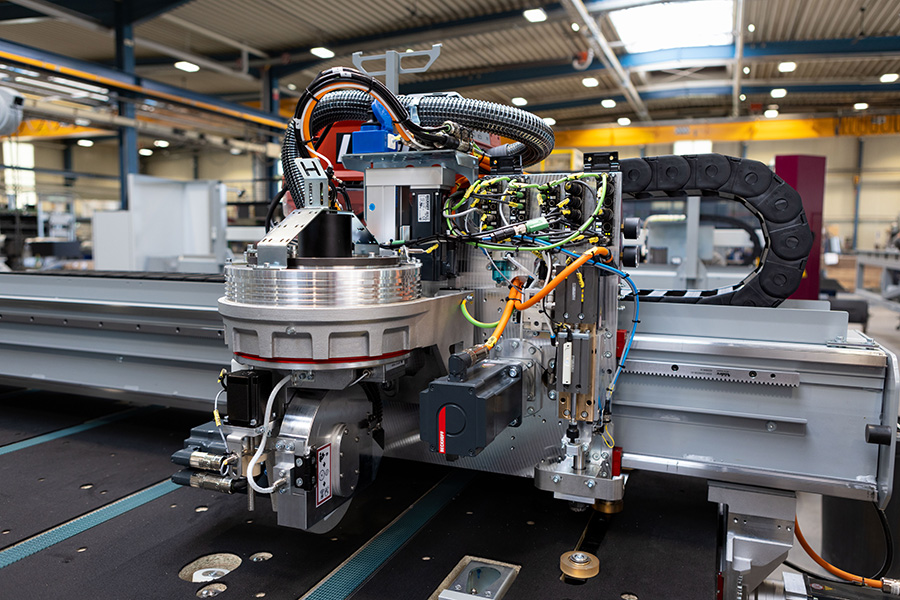

LiSEC’s DSC cutting technology is an advanced solution designed to address these challenges.

- Automatic tool and parameter selection based on glass type ensures consistently high quality.

- Integrated central lubrication minimizes maintenance effort and maximizes system availability.

- Edge-decoating technology with LiTEC Temperature Control provides precise process monitoring, enabling efficient removal of even complex coatings.

- Direct cutting technology eliminates mechanical components between the cutting head and wheel, guaranteeing maximum precision.

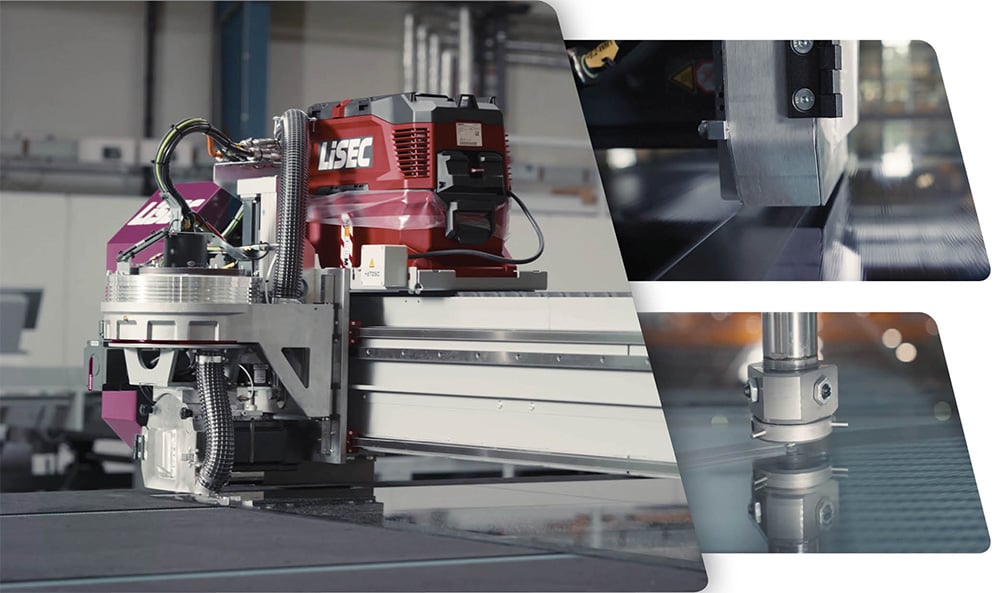

How Does the DSC Cutting Table Work?

The DSC system automatically detects the glass type and selects:

- The appropriate cutting wheel

- Optimal cutting pressure

- Correct speed and acceleration

It achieves speeds of up to 160 m/min for both edge-decoating and cutting—whether dealing with simple or complex coatings. The process is continuously monitored:

- Micro-chipping is minimized

- Cutting fluid and tool condition are automatically controlled

- Overheating and abrasive residue are prevented

- Real-time feedback keeps operators informed

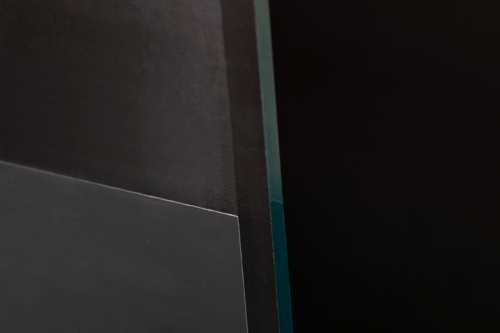

Edge Decoating in Practice

|

|

| The hydrophobic surface protection coating has been completely removed from the right edge of the glass. | The temporary surface protection film has been completely removed from the right edge of the glass. |

The edge decoating is carried out at high speed and with precision – even for special coatings such as solar control or thermal insulation glass, all in a single processing step.

- 160 m/min for standard solar/thermal coatings

- 112 m/min for EASYPRO protective coatings

- 40 m/min for TPF protective coatings

Fast and Safe Decoating with LiTEC Temperature Control:

The Advantages

- Process reliability: Automated control and real-time monitoring ensure consistent quality.

- Flexibility: Handles complex coatings without compromising speed or quality.

- Cost efficiency: Fewer machines, higher output—ideal for peak production and long-term efficiency.

This solution is perfect for glass processors aiming for top cutting quality with minimal waste. Production managers benefit from improved system utilization and reduced maintenance, while technicians working with new coatings gain a secure, reliable process foundation. LiSEC also offers hands-on workshops on cutting technology and edge decoating.

Summary

Modern float glass cutting demands quality, speed, and flexibility. LiSEC’s DSC cutting technology delivers all three, providing precise cutting, reliable processing of complex coatings, and minimized maintenance effort.