Temperature under control – focus on quality: LiTEC Temperature Control in glass cutting

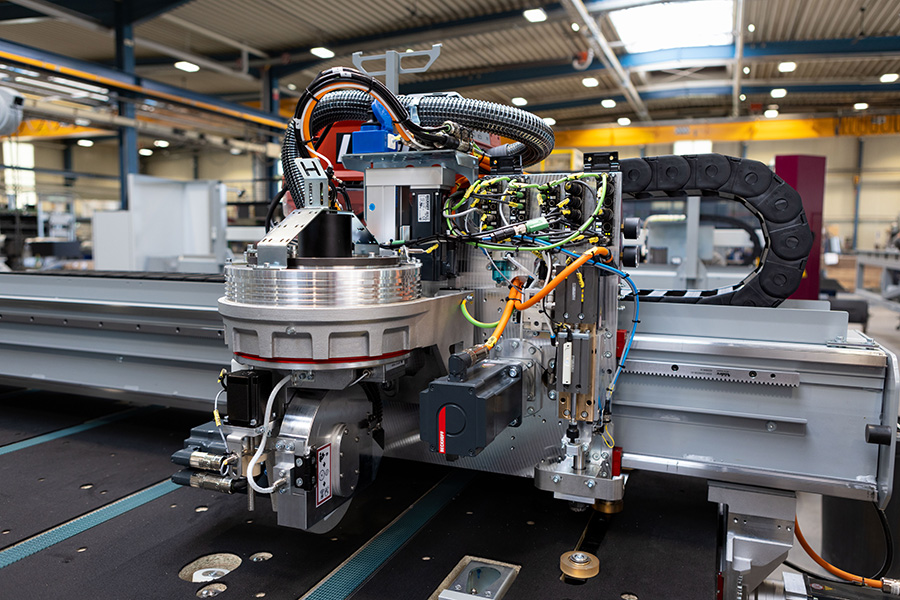

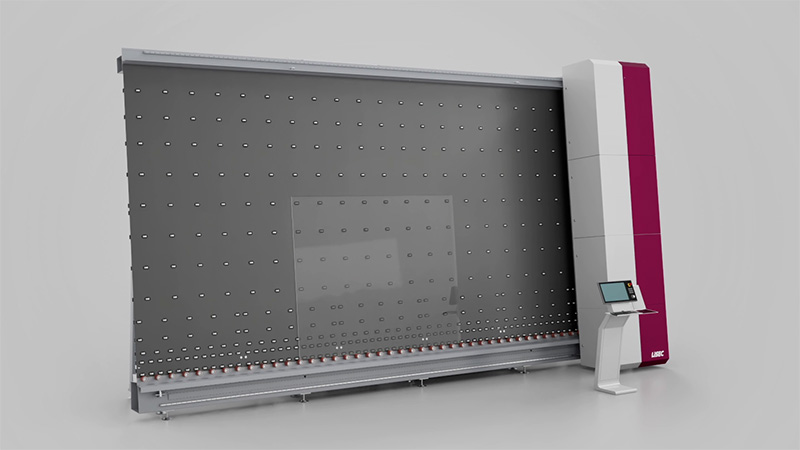

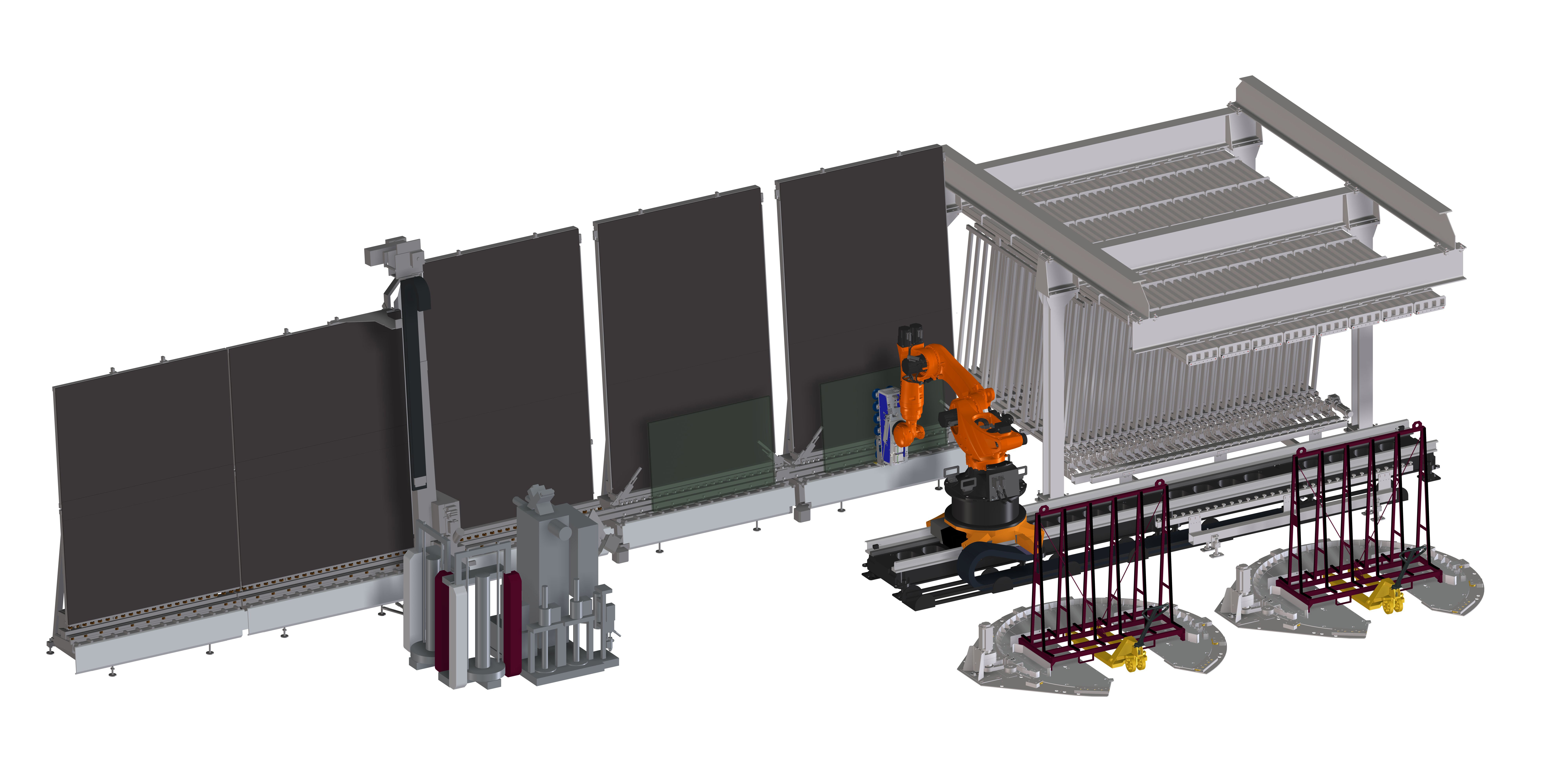

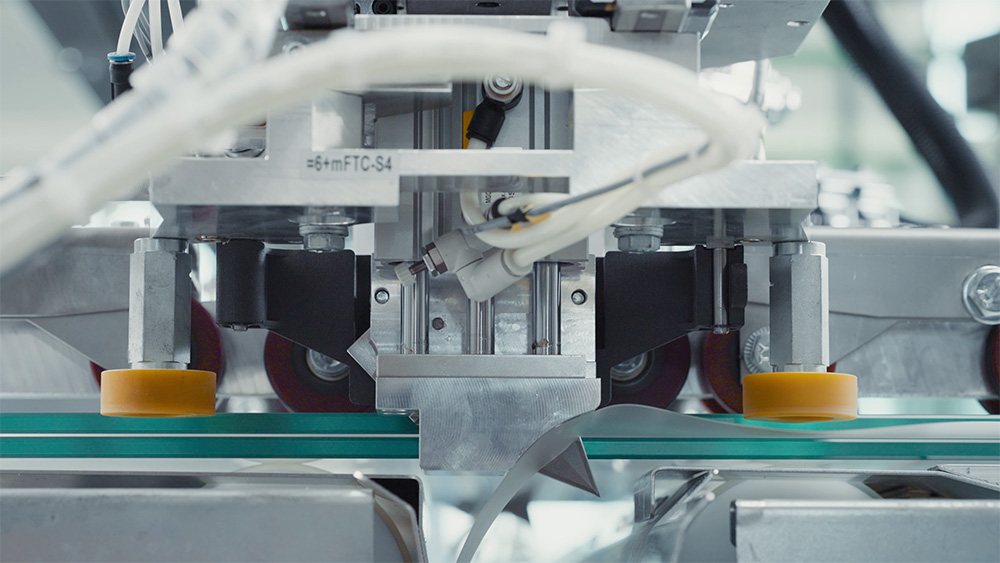

The decoating process is influenced by numerous factors, including the type, diameter and width of the grinding wheel, the rotational speed, the decoating speed and the type of coating. These parameters can have a significant impact on the quality of the edge decoating, especially if one factor causes the grinding wheel to overheat during the decoating process. The consequences: uneven results, increased wear and unnecessary costs. With LiTEC Temperature Control, LiSEC has developed a solution that addresses precisely this issue – for greater process reliability, quality and efficiency.

glass-cutting

4 min read