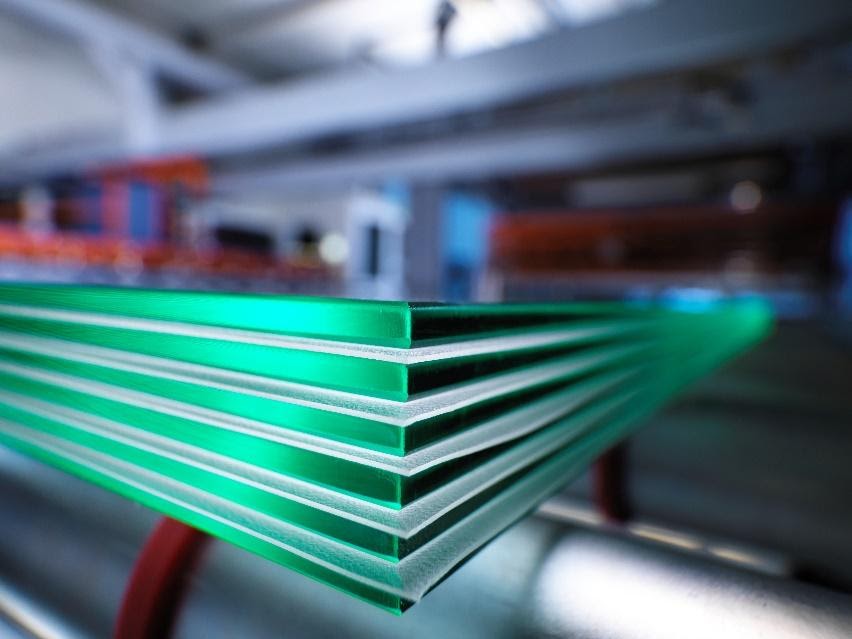

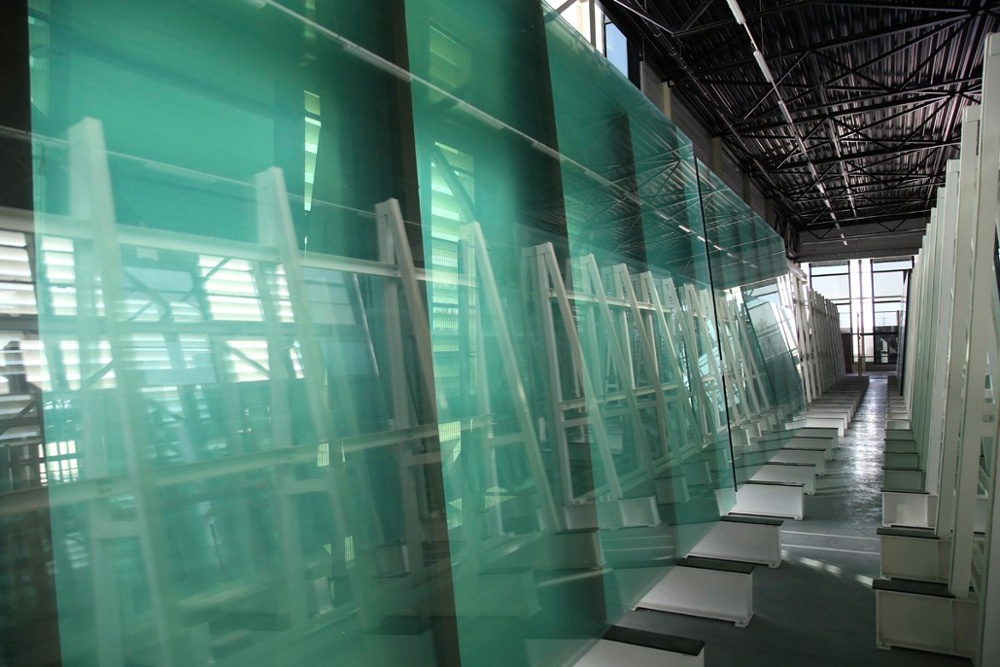

It is well known that laminated safety glass (LSG) is a material that is specifically processed because of its composition.But transport, storage space properties, handling, temperature, humidity, age of the glass and much more have another dramatic influence on glass cutting. “The best glass and the best machine can have processing problems if the storage is counter-productive.” Flat glass can be obtained in various qualities from the manufacturers and the quality naturally has an influence on the processing.This article, however, deals with influencing variables that each processing company has under control. 1. Glass storage The delivery of the flat glass is carried out with internal loader trucks.The internal loader racks are picked up by the truck and usually transport 20 tonnes of glass, which is stored in glass packages on the frame.Glass packages of 2.5 t or 5 t are commonly used. These individual packages are separated from each other by cardboard strips (spacers).The respective glass packages are individually placed in the storage areas by an employee in the glass storage with a lifting device attached to the gantry crane.The storage areas are L- or A-frames.These are simple steel constructions with a support surface on which the glass lites sheets stand. It is not obvious at first glance that the storage racks have an influence on subsequent processing, but they do have a clear effect. It is essential that the support surfaces remain at the same level.The glass edges must lie evenly on several support points and so the glass can be stored more or less free of stress (see image above).If, on the other hand, the supports are inclined or of different heights or the support surface is worn on one side, stress is induced in the glass, which can be noticeable in the glass cutting process through increased glass breakage. 2. Glass temperature and humidity Hot, cold, warm, dry, moist:Essential factors that should be considered in order to optimise the glass cutting process.Laminated glasses consist of a laminated layer of two flat glasses joined together by a foil (PVB, EVA, Setry glass, etc.).Due to their physical properties, glass and foil have different temperature behaviour and this must be taken into account during processing, especially when glass cutting. Glass is a brittle material.The colder the more brittle, the warmer the softer.The foil has similar properties, but unfortunately in a different temperature range.Air humidity also influences the properties of the foil.