Quality plays a decisive role in insulating glass production. Customers rely on the properties of the products remaining the same and tolerances defined in various standards being adhered to. Production companies can only meet these requirements if they monitor the conditions under which the products are manufactured and take action if necessary. If quality defects occur, it is particularly important to be able to trace how they came about in order to define the necessary measures. With lis.qualitypass, LiSEC provides its customers with a tool that significantly increases traceability in insulating glass production.

TRACEABLE QUALITY IN INSULATING GLASS PRODUCTION

The data that lis.qualitypass works with is provided directly by the machines and the production planning system, collected by lis.edgebox and transferred to the Microsoft Azure Cloud. There, this data is processed accordingly, pre-calculated and stored in databases for lis.qualitypass. We call this combination of machine data interface, production planning system, edge box and cloud infrastructure the LiSEC IoT platform.

The IoT platform as the basis for reliable data

The basis for data-supported decisions is reliable data and information. LiSEC provides its customers with an IoT platform that is based on four pillars:

- Network connection of machines and standardized data structure

In order for data to be collected from production systems, it is essential that they are connected to the network. LiSEC machines have been meeting this requirement for many years because automation in production requires machine networking. Furthermore, it is essential that the data structures of the machines follow a standardized schema. This makes it possible to collect data from different systems and still use universally valid algorithms to derive information from this data. - Reliable management of edge boxes

The central component for collecting, normalizing and filtering the data is lis.edgebox. This is available both in physical form as an industrial PC and virtually as an image for common virtualization environments. With a global network of hub systems on all continents, LiSEC provides an infrastructure that enables centralized and reliable management as well as regular updating of the edge boxes. - Secure cloud infrastructure

To ensure that customer data is transmitted and stored securely, LiSEC relies on its long-standing partnership with Microsoft and uses the security technologies of the Azure cloud. The data is processed there and stored in a structured form so that it can be used by various applications. - Applications

LiSEC provides various applications that create considerable added value for the respective customer based on the data. As a result, customers benefit twice over - they have reliable machines and data-based transparency that enables them to make the best possible use of the machines.

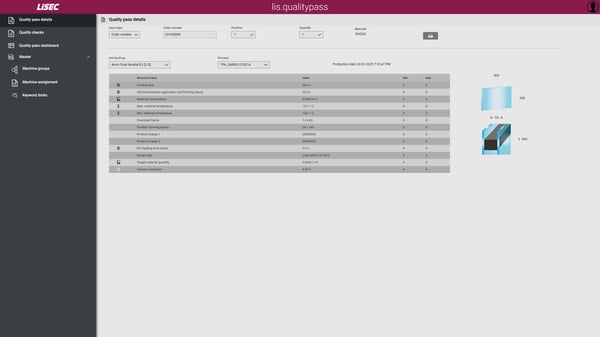

How lis.qualitypass works

Data is generated at various points in the production of insulating glass. On the one hand, the machine itself records measurement data such as pressures, temperatures and times. On the other hand, the production planning system provides information on the structure of the insulating glass.

The lis.edgebox collects this data from the machines and the production planning system and transfers it to the Microsoft Azure Cloud for further processing. The data is aggregated and correlated in the cloud environment. In addition, manual tests can be digitally recorded, managed and linked to the recorded data.

Requirements for the use of lis.qualitypass

To be able to use lis.qualitypass, the following requirements must be met:

- The machines on the insulating glass line must already generate and provide the required data.

- The GPS.prod production planning system must be used in version 22.05 or higher.

The advantages of lis.qualitypass

lis.qualitypass increases transparency in production so that quality defects can be recognized and linked to influencing factors. Potential for improvement can thus be identified and production control made easier. Automatically recorded measurement data and manually recorded quality inspections serve as the basis.

More About software?

- Data as a chance for the production of the future

- lis.analytics – Transparent production in the flat glass industry

- lis.edgebox – Revolution in remote maintenance and data acquisition

.jpg?width=352&name=beitragsbild1-allgemein-beitrag4-glass-polishing-edge-processing-lisec.2022%20(1).jpg)