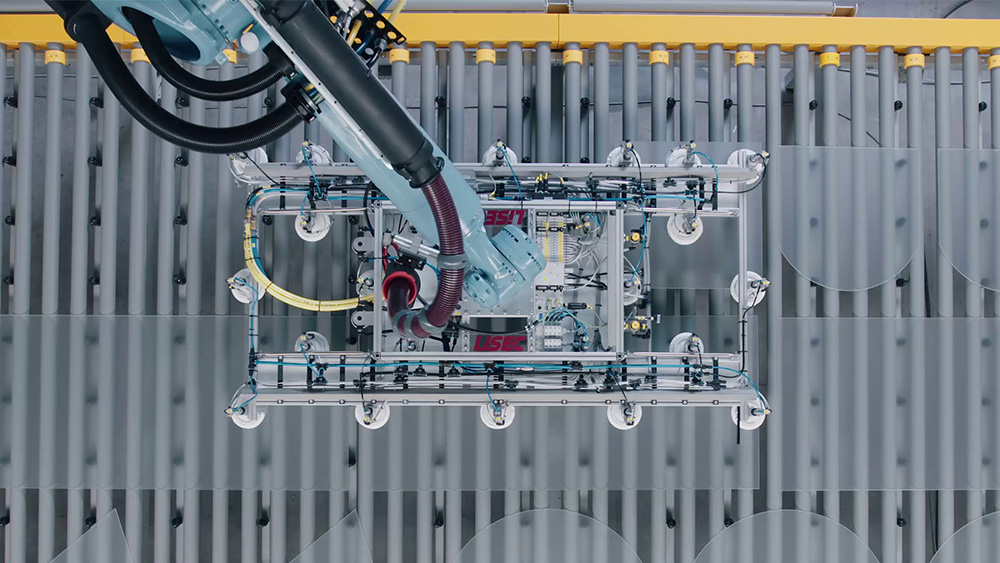

World's fastest Laminated Glass Cutting

Growing demand for better burglary and noise protection as well as new national standards such as DIN 18008 require the processing of ever larger quantities of laminated glass. To keep pace with these demands, we are introducing an innovative laminated glass cutting system that cuts more glass in less time - with less waste and fewer labour requirements. Are you ready to take your production efficiency to the next level?

glass-cutting

5 min read