In the insulating glass industry, we like to talk about glass. But the main quality feature of an insulating glass element, the gas tightness, is mainly achieved through a correctly pressed spacer.

LiSEC has been developing solutions for the perfect butyl line and gapless pressing since the 1990s. Our latest butyl extruder is more precise, more compact and allows any desired level of automation.

A gas-tight IG element protects the noble gas on the inside while keeping moisture on the outside, thereby preventing any fogging of the inside panes. With rigid spacers, the gas-tightness between the glass and the spacer is ensured by the butyl seal.

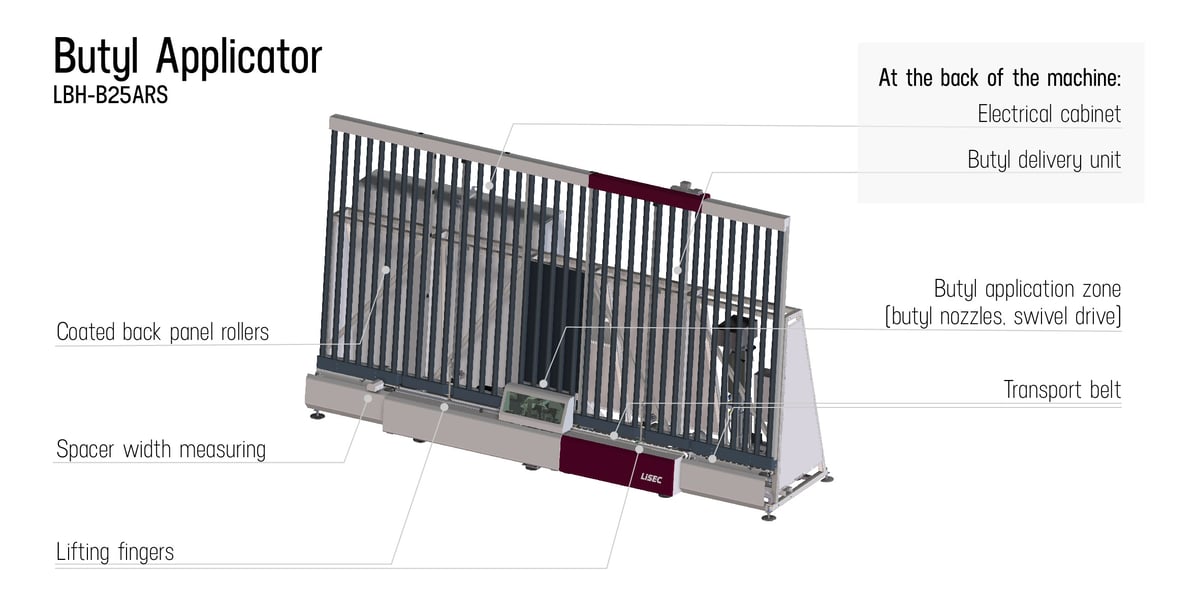

The butyl material can be applied semi-automatically by machines such as the LBH-25V or LBH-60M or fully automatically by an LBH-B25ARS.

AUTOMATION VIA MOUSE CLICK!

OUR MOST ADVANCED BUTYL APPLICATOR

Our butyl extruder represents 30 years of experience. Here are the most important innovations in 2023:

ALL ADVANTAGES AT A GLANCE

- Precise and uninterrupted butyl application

- Volumetric butyl quantity measurement with adaptive control

- Automatic height adjustment of the butyl line

- Recipe-controlled adaptation to different corner radii

- Processing of Georgian bar frames

- Servo-controlled lift finger system

- Uninterrupted production through material container change

- Perfectly non-stick rear wall rollers

- Compact design

The main parts of the BUTYL APPLICATOR

WATCH THE BUTYL APPLICATOR LBH-B25ARS AT WORK