Capture production data directly from the production line – without having to go through a PC? The LiSEC Mobile App offers a practical solution here: it enables digital feedback directly on site, thereby significantly simplifying the entire process.

Control production processes digitally and on the go

In modern glass manufacturing, it is crucial to keep track of the production status at all times. The LiSEC Mobile App “Production Control” enables exactly that: Feedback from production directly via mobile devices.

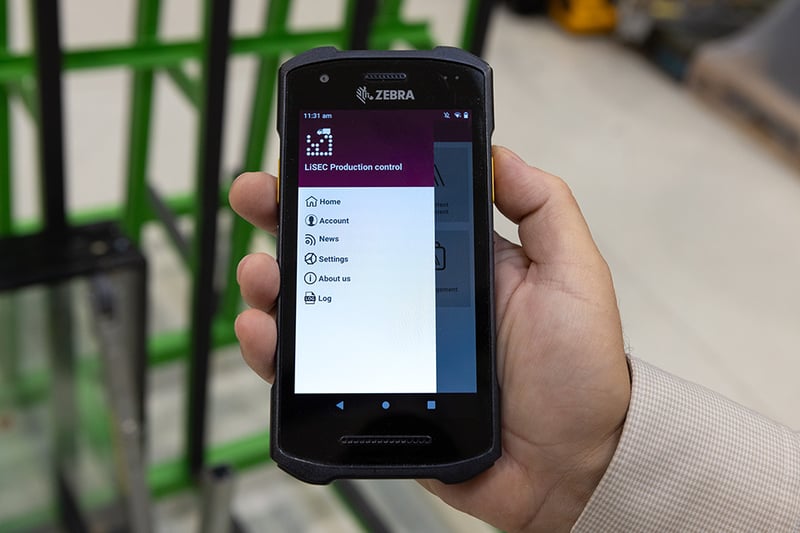

The app is designed as a native Android application and runs on robust industrial devices such as the Zebra TC27 or TC22. It replaces manual feedback on the PC and offers a variety of functions that can be used directly at the point of action.

APP FEATURE HIGHLIGHTS

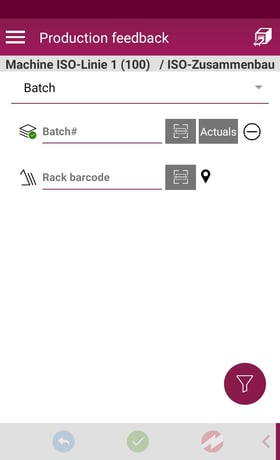

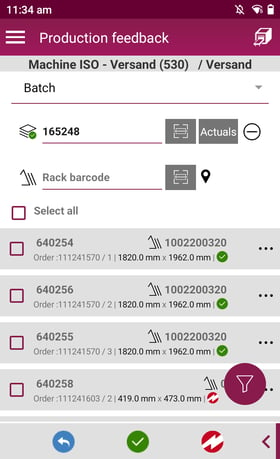

- Step-by-step feedback: Completion notifications directly on the machine or rack.

|

|

|

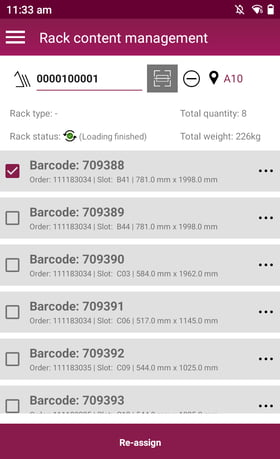

- Rack management:

- Transfer or add panes

- Breakage notification

- Order picking and delivery note printing

- Order picking: Combine multiple racks into one delivery, including delivery note printing for items actually delivered.

- Workflow control: Completion notification only possible once previous work steps have been completed.

- Barcode-supported identification: Orders, batches, and delivery racks are automatically recognized with the smart barcode.

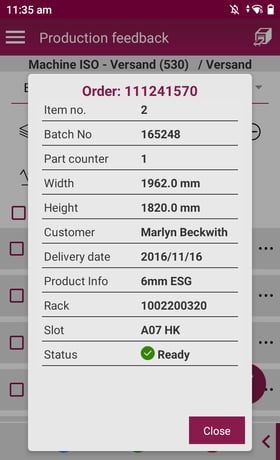

- Verification function: Comparison of target and actual loading of a rack.

The app accesses the database live, providing an up-to-date overview of the production status including filter options for completion, quality status, or delivery date.

Availability and requirements

The LiSEC Mobile App is always available through our sales department. To use the app, a LiSEC GPS.prod system with work-step assignment and capacity planning (minimum version 4.13) is required. The app is also compatible with GPS.order starting from version 5.6.

Summary

The LiSEC Mobile App offers a practical way to record and process production data directly on site. It supports both the feedback of individual work steps and the organization of shipping processes and order picking. This contributes to a better overview and control of production processes – without additional steps or media breaks.