Laser technology offers numerous advantages including precision, speed, contact-free processing and minimal thermal load. In which areas of flat glass processing can laser technology currently be meaningfully used?

Application 1: surface treatment

Logos, serial numbers or decorative patterns are often applied to glass. Conventional engraving methods can lead to cracks, uneven depth or thermal effects. Laser engraving enables precise and even markings without direct contact with the glass surface, thus reducing the risk of defects and damages.

Application 2: decoating

Pulsed infrared lasers are used for contact-free ablation. Coatings such as paint, mirror coatings, enamel, low-e coatings or conductive coatings can be removed with razor-sharp edges. Neither grinding marks nor grinding material residue are left on the pane. The exposed glass remains undamaged and unclouded.

Application 3: Glass labeling

The marking of glass is becoming more and more important for product tracking, brand awareness and anti-counterfeiting. The LMS (Laser Marking System) from LiSEC can be used to apply letters, numbers, logos and machine-readable codes to glass surfaces in an abrasion-resistant manner. Marking lasers and reading technology can be integrated into a production line or a cutting table, or even used as a mobile system. Whether it's barcodes, data matrix or QR codes, alphanumeric characters, serial numbers or ESG stamps – LiSEC's laser marking technology offers flexible and permanent labeling options.

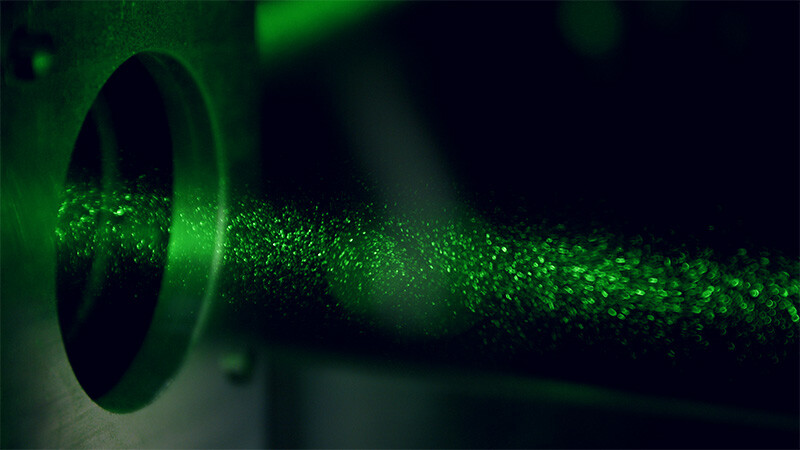

Application 4: laser drilling

Lasers provide a precise, non-contact and fast method for drilling glass. Traditional methods such as mechanical drilling or water jet cutting can lead to cracks or uneven holes and require large amounts of water and high forces, resulting in high costs and wear. With a laser, small and large holes can be drilled precisely and almost without force, leaving the glass undamaged. LiSEC Laser Drilling Processing (LDP-A) enables clean and precise holes with minimal material loss and is characterized by flexibility, efficiency and environmental compatibility.

Conclusion

The advantages of laser technology are precision, speed, contact-free processing and minimal thermal load. These properties make it ideal for challenges in glass production, especially in surface and interior processing, decoating and labelling.