Insulating glass is a key factor for energy efficiency and living comfort. It provides thermal and acoustic insulation, significantly reducing heating and cooling costs.

WHAT IS INSULATING GLASS?

The name reveals its function: insulating glass insulates—both heat and sound. While historic box windows with single panes and air gaps were common, modern insulating glass consists of multiple panes separated by spacers:

- Double glazing: two panes of glass, one chamber in between

- Triple glazing: three panes of glass, two chambers in between

- Quadruple glazing: four panes of glass, three chambers in between

As the number of panes increases, both thermal insulation and properties such as acoustics or burglary resistance improve. Coatings, spacers, edge seals, and filling gases play a central role in the quality, durability, and strength of the glass or glass unit.

SPACERS AND NOBLE GAS FILLING: THE KEY TO INSULATION

The development of spacers shows technological progress:

- Early on: wooden spacers in box windows

- Industrial evolution: steel and aluminum spacers

- Recent years: warm-edge technologies, metal-plastic hybrids, and thermoplastic materials

The spacer not only defines the gap between panes but acts as a bridge between them. Materials with low thermal conductivity prevent thermal bridges and ensure that insulating glass delivers full insulation performance. A high plastic content or thermoplastic materials increase efficiency and positively impact energy consumption. In addition to thermal insulation, the spacer also contributes to sound reduction, especially when combined with laminated safety glass. This way, security (burglary resistance, residual load capacity) and acoustic insulation can be optimally combined.

To fully unleash its insulating properties, the spaces between the panes are filled with a noble gas—either krypton or argon—and then sealed. To prevent any gas leakage, the insulating glass unit is hermetically sealed with butyl sealant. This prevents gas from escaping and guarantees the longevity of the insulating glass package.

The combination of spacer and noble gas not only influences safety or acoustics but also makes a major contribution to resource conservation. Good insulation keeps warmth inside during winter and heat outside during summer, significantly reducing heating and cooling costs. The trend is toward further optimization of insulating glass, focusing particularly on spacer frames, materials used, and coating combinations.

FROM PANE TO FINISHED INSULATING GLASS: THE PRODUCTION LINE

A modern insulating glass line consists of several process stations:

1) Loading: Glass panes are placed on the line manually or automatically2) Washing: Cleaning of individual panes with brushes followed by drying

3) Inspection: Visual or machine check for contamination or defects

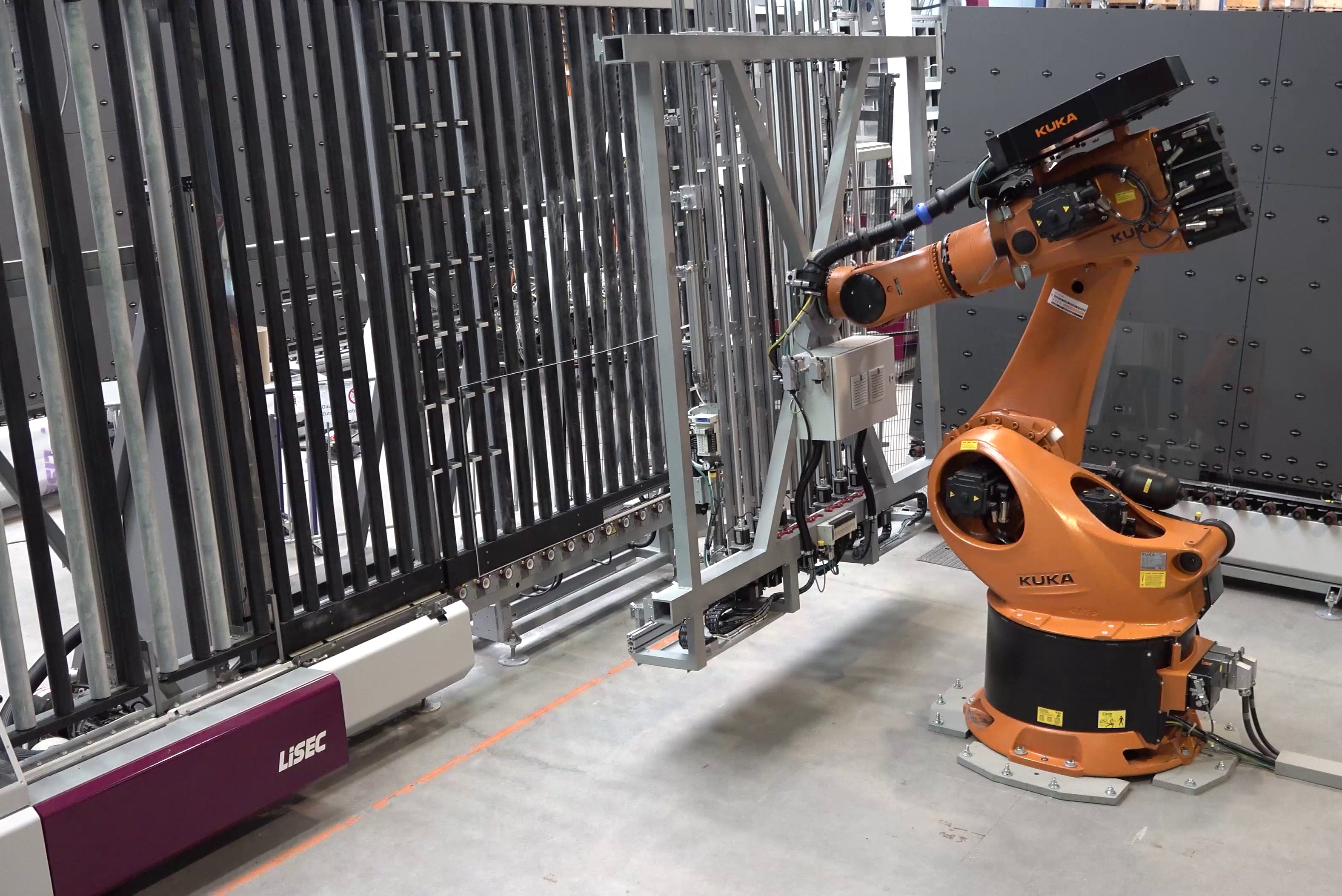

4) Spacer frame placement: Robots or operators position spacers precisely

5) Assembly and gas filling: Panes are aligned in the gas filling station, gas is added, and the glass unit is sealed

6) Sealing station: Final sealing with sealant for hermetic closure and mechanical stability

7) Unloading: Finished insulating glass is removed and prepared for shipping or further processing

Each station is designed for high precision and quality so that the final product meets the desired standards for thermal insulation, safety, and acoustics.

Each station is designed for high precision and quality so that the final product meets the desired standards for thermal insulation, safety, and acoustics.

Learn more about insulating glass in our podcast LiSTEN LiSEC.