Production companies in the flat glass industry are facing the challenge of optimizing their processes to increase productivity and quality like never before. Data and its analysis are playing an increasingly important role in this. If reliable data can be obtained from the individual production plants, valuable insights can be gained, which contributes to considerable transparency and facilitates well-founded decisions. With lis.analytics, LiSEC provides production managers with a data-supported tool for monitoring production performance on the basis of real-time data and subsequently optimizing it through appropriate measures.

The IoT platform as the basis for reliable data

The basis for data-supported decisions is reliable data and information. LiSEC provides its customers with an IoT platform that is based on four pillars:

- Network connection of machines and standardized data structure

In order for data to be collected from production systems, it is essential that they are connected to the network. LiSEC machines have been meeting this requirement for many years because automation in production requires machine networking. Furthermore, it is essential that the data structures of the machines follow a standardized schema. This makes it possible to collect data from different systems and still use universally valid algorithms to determine key figures such as Overall Equipment Effectiveness (OEE). - Reliable management of edge boxes

The central component for collecting, normalizing and filtering data is lis.edgebox. This is available both in physical form as an industrial PC and virtually as an image for common virtualization environments. With a global network of hub systems on all continents, LiSEC provides an infrastructure that enables centralized and reliable management as well as regular updating of the edge boxes. - Secure cloud infrastructure

To ensure that customer data is transmitted and stored securely, LiSEC relies on its long-standing partnership with Microsoft and uses the security technologies of the Azure cloud. The data is processed there and stored in a structured form so that it can be used by various applications. - Applications

LiSEC provides various applications that create considerable added value for the respective customer based on the data. As a result, customers benefit twice over - they have reliable machines and data-based transparency that enables them to make the best possible use of the machines.

LIS.analytics

In order to increase productivity in production, managers need know-how, but also reliable information about where there is potential for improvement. By using lis.analytics, this information is available in real time and in a reliable form, so that decisions can be made on the basis of sound data. This software currently offers two functional areas, Live Performance Monitoring and Productivity Analysis.

LIS.analytics: Live Performance Monitoring

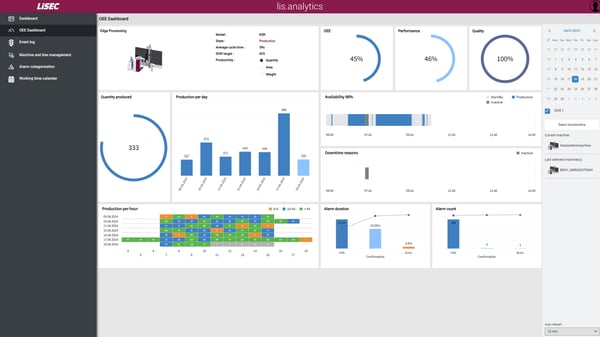

With the help of Live Performance Monitoring, it is possible to visualize various data from production in real time - and this can be individually adapted. By using individual dashboards, each user can display the information they need in a targeted manner. Key figures for a machine can be displayed directly in production on large screens, as well as comprehensive dashboards for the entire production process in the production management office. The information ranges from produced quantities or areas to product mix and alarm statistics - all live and in real time.

With the help of Live Performance Monitoring, it is possible to visualize various data from production in real time - and this can be individually adapted. By using individual dashboards, each user can display the information they need in a targeted manner. Key figures for a machine can be displayed directly in production on large screens, as well as comprehensive dashboards for the entire production process in the production management office. The information ranges from produced quantities or areas to product mix and alarm statistics - all live and in real time.

LIS.analytics: Productivity Analysis

More in-depth analyses require not only data, but also key figures based on it, such as OEE (overall equipment effectiveness). With the OEE dashboard, LiSEC enables its customers to gain direct insight into where the greatest potential for improvement lies. The three components availability, performance and quality are considered individually. In contrast to live performance monitoring, it is possible to select any date and thus also analyze historical data. Several machines can be combined into production lines so that the key figures are also calculated automatically for entire lines. The data can be viewed for an entire calendar day as well as for individual shifts. In combination with the OEE Dashboard, lis.analytics offers the option of creating a shift calendar and assigning it to individual machines or lines. This allows the same shift to be compared over several days or with another shift. The target for piece, area or weight can be defined so that the dashboard graphics are displayed in line with the respective production target.

More in-depth analyses require not only data, but also key figures based on it, such as OEE (overall equipment effectiveness). With the OEE dashboard, LiSEC enables its customers to gain direct insight into where the greatest potential for improvement lies. The three components availability, performance and quality are considered individually. In contrast to live performance monitoring, it is possible to select any date and thus also analyze historical data. Several machines can be combined into production lines so that the key figures are also calculated automatically for entire lines. The data can be viewed for an entire calendar day as well as for individual shifts. In combination with the OEE Dashboard, lis.analytics offers the option of creating a shift calendar and assigning it to individual machines or lines. This allows the same shift to be compared over several days or with another shift. The target for piece, area or weight can be defined so that the dashboard graphics are displayed in line with the respective production target.

The advantages of a cloud service

lis.analytics is a pure cloud application and this has significant advantages. lis.analytics can be accessed from anywhere, regardless of whether you are in the company network or on the move via VPN. Cloud applications are also kept up to date by LiSEC so that all customers always benefit from the latest updates. Thanks to the cooperation with Microsoft and its cloud infrastructure, LiSEC's customers benefit from its high availability and reliability as well as state-of-the-art information security. For example, single sign-on (SSO) allows customers to use their own user names and passwords and thus also policies, which means that a user lockout has an immediate effect on all services.

Product availability and next steps

lis.analytics is available immediately and will be set up by LiSEC service staff. Please contact us for further information.