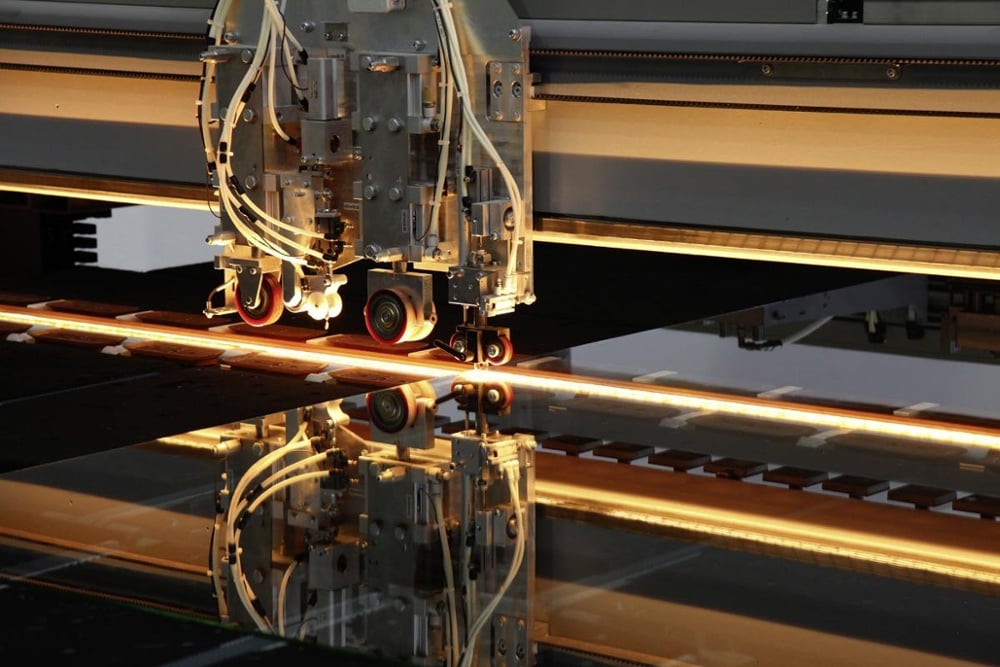

How the production affects the glass cutting process

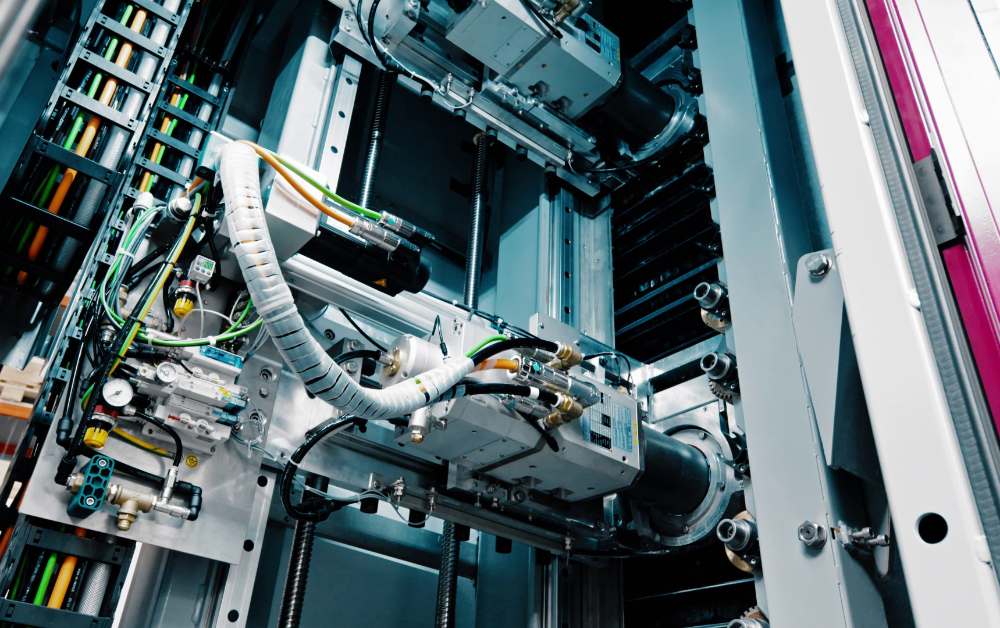

Everyone who processes this material knows that laminated safety glass (LSG) is unconventional and requires a great deal of sensitivity. The LSG cracks and chips and finally the question arises: What was to blame for the breakage? Was the cutting pressure too low? Was the crushing pressure too high? Cutting speed, acceleration, crushing roller feed, cutting wheel angle, temperature, cutting oil or was it tension in the glass during production in the glassworks? The influencing factors are unmanageable and glass qualities fluctuate constantly.

glass-cutting

14 min read