How you enjoy major advantages with the professional seaming of glass edges

In glass edge processing, cutting the glass sheet is directly followed by the seaming process. Fully unprocessed glass edges exhibit overbreaks and underbreaks, conchoidal fractures, as well as micro-cracks along the broken edge. These types of damage are caused by the cutting wheels used in the cutting process. It is possible to reduce these cutting wheel-induced defects by using the cutting wheel at the appropriate angle for the respective glass, and by using a maintained cutting wheel axis and cutting wheel holder (service life in accordance with the manufacturer's specifications). This is important because any damage to the glass edge reduces the edge strength and in doing so also significantly increases the risk of spontaneous breakage.

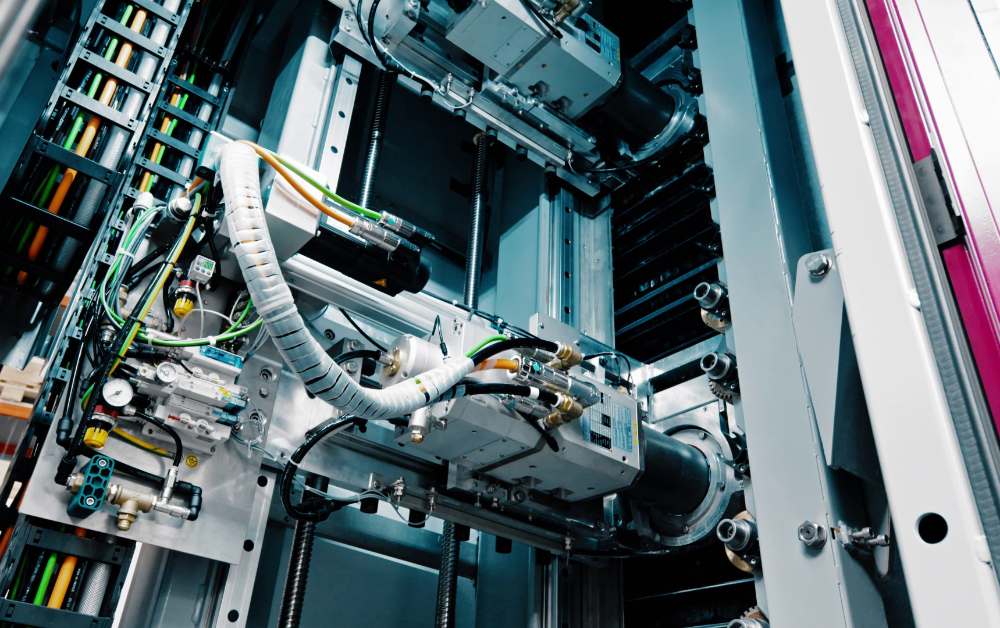

glass-edge-processing

8 min read